Artificial intelligence is transforming the way Domtar’s sawmills operate.

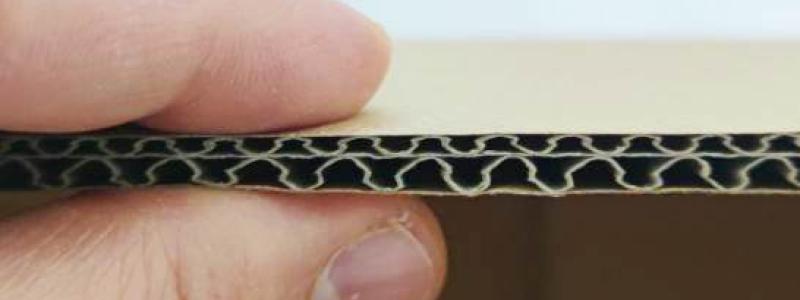

According to Domtar, the wood manufacturing industry is highly efficient. Every part of every tree we harvest can be made into useful products. Whatever can’t be used as lumber is chipped to become pulp and paper, and other residues are used to generate energy as biomass.

Domtar has identified ways to use AI modeling and machine learning to significantly improve product quality over the past two years at its mills in Glenwood, Arkansas; Cross City, Florida; Thunder Bay and Atikokan in Ontario; and Normandin, La Doré and Senneterre in Quebec. The company can also use AI modeling to assess wood for compliance with customer specifications.

“AI allows us to be more precise and consistent,” says Carl Lévêque, quality superintendent for all planer mills in the company’s Wood Products business unit. “There’s a lot less waste”, as quoted by Domtar.

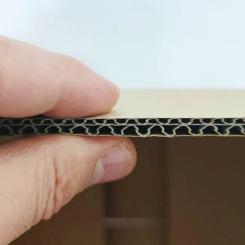

Soon after arriving at the planer mill, boards are scanned by sensors. The scanner analyzes the wood’s composition, grading it visually and identifying inconsistencies that are undetectable to the human eye. This was once a labor-intensive and potentially hazardous task.

AI models then assess wood for each individual specification.

“The Normandin mill makes around 15 unique lumber products, and each one needs to meet customer specifications,” explains Carl. “Wood that will be used to build homes is subject to strict building code standards, and customers may have additional specifications.”