Toscotec will supply a new tissue line PM7 for the Grigeo Group’s facility in Grigiškės (Vilnius, Lithuania). This repeat order marks a significant milestone in a partnership spanning over 15 years between the two companies, following the successful installation of the PM6 tissue line in 2013 and previous smaller projects involving Yankee Dryers and Hood replacements on other machines within the group.

This new tissue line, with a daily production capacity of up to 250 tons, highlights the Grigeo Group’s strategic investment to double paper production while also reducing energy costs. It is designed with Toscotec’s cutting-edge technology to significantly reduce environmental impact: specifically decreasing the use of gas and fresh water at the production site.

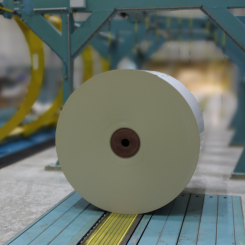

The AHEAD 2.2L tissue machine will have a paper web width of 5500 mm and a design speed of up to 2200 meters per minute, setting a benchmark for sustainable tissue manufacturing. The machine is designed to include TT Headbox with dilution control system for superior sheet formation, TT Next Press to enhance the drying process, and the most innovative 18-foot Steel Yankee Dryer TT SYD, which is a cornerstone of efficiency and high-performance.

The machine features Toscotec’s state-of-the-art products from Energy Pack. It includes TT Turbo Dryer, developed to increase post-press dryness by using the available energy in hood exhaust, and the gas-powered TT Hood-Duo system with TT Swing technology, designed to optimize the drying process based on different production grades. It is also configured for future installation of electric heating batteries, allowing for the combined use of natural gas and electricity in the drying process. Furthermore, the TT Drying Equilibrium’s integration – with its automatic hood balancing system – will enhance the air system by boosting the working speed of the fans and reducing the natural gas consumption of the burners.

The supply also includes the full Stock Preparation Plant, Water Cycle, broke line from converting, as well as the complete electric plant, and TT Brain DCS system designed by Toscotec.

A complete Optima 2600 Slitter Rewinder for double sheet width equipped with two Unwind Stands, automatic shaft handling system, a dedicated Dust Removal system and Electrification & Control complete the scope of supply.

“The investment in one of the fastest standard paper machines on the market – PM7 – will enable Grigeo Group to double its hygienic paper production capacity and meet the growing demand in the Baltic, Scandinavian, and Western European markets. PM7 technology will ensure greater production efficiency and flexibility, while strengthening the Group’s position in strategic markets,” says Tomas Jozonis, CEO of Grigeo Group.

Tomas Jozonis, CEO of Grigeo Group. Photo: Grigeo Group

“It is with great honor that we embark on Project PM7, bringing our client’s vision to life with our cutting-edge technology for energy efficiency while increasing production. This repeat order from a valued partner – with whom we have cooperated for more than15 years – demonstrates the depth of our established collaboration. Our mission consistently prioritizes the customers’ needs, and we are proud to be working alongside the Grigeo Group on this important initiative to foster their growth,” states Alessandro Mennucci, CEO of Toscotec.

About Grigeo Group

Founded in 1823, Grigeo Group is the only paper and wood industry company in Lithuania and one of the largest in the Baltic countries. The Group comprises the following companies: Grigeo Tissue, Grigeo Hygiene, Grigeo Paper Packaging, Grigeo Klaipėda, Grigeo Packaging, Grigeo Baltwood, Grigeo Recycling, Mena Pak, and Grigeo Tissue Sp. z o. o. In its processes, Grigeo Group covers an almost complete cycle of manufacturing wood and paper components. Grigeo Tissue produces 70,000 t/y of tissue products, which are also exported to 19 countries.