Process Heat is by far the largest energy consumer in the industry and is still often produced by burning fossil fuels. With the rise of cheap but volatile electricity from renewable energy technologies and increasing carbon prices, electricity becomes more and more economical compared to fossil fuels. Power-to-Heat plants are able to deliver large amounts of process heat in the desired temperature range and enable companies to profit from price fluctuations at the wholesale electricity markets. Instead of providing that flexibility by using large battery storages, industrial companies with process heat demand have the opportunity to utilize much cheaper thermal energy storages that are charged by Power-to-Heat plants.

Net-Zero process heat with flexibility

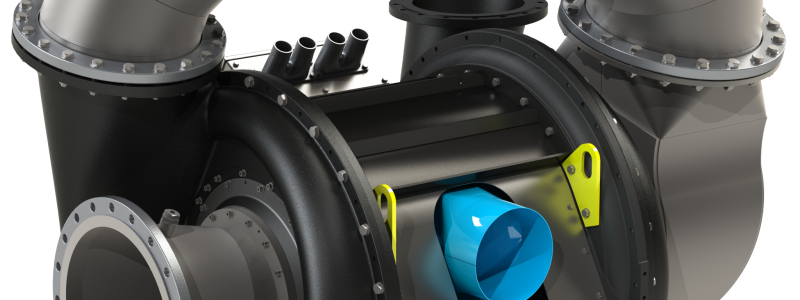

Otto Junker Solutions developed such a Power-to-Heat plant and pursues the high temperature approach. The plant is able to heat up air to temperatures of 200 °C to 1.200 °C which is stored in a thermal storage or used directly for the process. The high temperatures enable a smaller storage unit due to more energy being stored in the same amount of space. The stored energy can now be discharged continuously by guiding air through the storage and a heat exchanger where the heat is transferred onto the used heat carrier of the industrial process. This way the Power-to-Heat plant can bring steam or heat thermal oil, water or air up to the required temperatures. Using a closed loop, the system has an efficiency of 95 % while the Power-to-Heat plant reaches an efficiency of 98 %. The combination of Power-to-Heat plant and a thermal storage enables companies the complete electrification of process heat and therefore a net zero production without the reliance on baseload power plants.

Read more about Power-to-Heat on our website

Combining Power-to-Heat and Biomass

Some industries however have the possibility to achieve climate neutrality by combining biomass and Power-to-Heat plants instead of a storage. Especially the pulp and paper and the wood industry use large amounts of biomass which is generated as waste from their production processes to generate heat. By using the electric heater during times with low electricity prices and biomass in between, companies can massively lower their initial investment, profit from cheap and intermittent electricity and become carbon neutral quickly.

Read more about Power-to-Heat on our website