After installation of a long nip style press in the board machine at Porstendorf, Germany, MultiFlex V3 press felts from Voith Paper were installed for start-up. The decision was thus made to introduce a clothing supplier not previously active in Porstendorf. The concept was customized. In particular, the outstanding service at start-up confirmed to the team in Porstendorf that the right decision had been made in choosing the clothing supplier. Meanwhile the new press has already been running several weeks and in summary it can be said that all technological specifications have been met or surpassed. "Especially noteworthy are the 52% dry content achieved and the width shrinkage which was reduced by more than 10%", observes plant manager Steffen Söll.

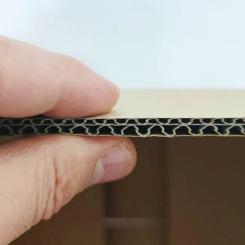

The board machine with 2.32 m net width and a speed of 80 m/min produces 40,000 tons of chipboard per year. At the turn of the years 2009/2010, the two previous reversed presses were replaced by a long nip style press for press loads up to 500 kN/m. A straight-through press was positioned at the end of the press section for setting the desired surface characteristics. The goals of the conversion were: improvement of the energy balance, reduction of production disturbances due to vaporization bubbles and improvement of ply bond strength.

The government of British Columbia has announced plans to institute a "stumpage deferral program that...

Western Forest Products Inc. and Qwoqwnes Forestry Holdings Limited Partnership, an entity beneficially owned and...

The global paper bag market is steadily expanding, valued at approximately US$6.4 billion in 2025...

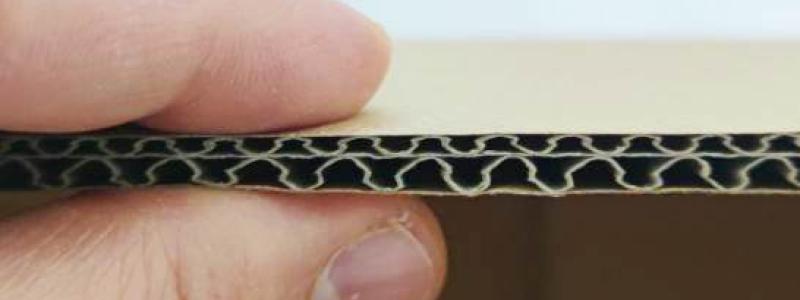

Atlantic Packaging Products announces that its packaging solution for the Zavida Coffee Roasters® Organica coffee...

Smurfit Westrock operates a large paper mill in Piteå, northern Sweden, which is Europe’s largest...

One.five, a Hamburg-based provider of sustainable packaging solutions developed using advanced AI technologies, is supplying...

Georgia-Pacific announced that Nate Medina has been named senior vice president and general sales manager...

U.S. Customs and Border Protection (CBP) on September 30, 2025 announced publicly its investigation into...

SPAPER 2027 – International Exhibition of Machinery and Equipment for Pulp, Paper, and Cardboard, will...

Koehler Paper takes step towards future-proof POS printing solutions Koehler Paper, a Koehler Group company...

Job listings