Known for its world-leading process automation, measurement and control solutions for the pulp, paper and process industries, Metso is now making its products and solutions available for the corrugated industry, too. Passing on its in-depth experience from the paper industry to the corrugated industry, Metso will enable box makers to achieve visible improvement in their manufacturing processes. The products and solutions improve board quality in addition to increasing corrugator performance and machine utilization.

“For Metso, it is a natural move to also serve the corrugated industry. We understand the paper and board processes inside out and know the machines and their requirements well,” says Mikko Talonen, Product Manager, Automation, Metso. “Now we will offer our technology and expertise specifically to the corrugated industry.”

The demand for corrugated packaging is increasing since more and more people do their shopping online. As the boxes used to deliver the goods need to be durable, quality control plays an important role in manufacturing corrugated board. With advanced quality control solutions, the quality of corrugated board and production performance of corrugators can be significantly improved.

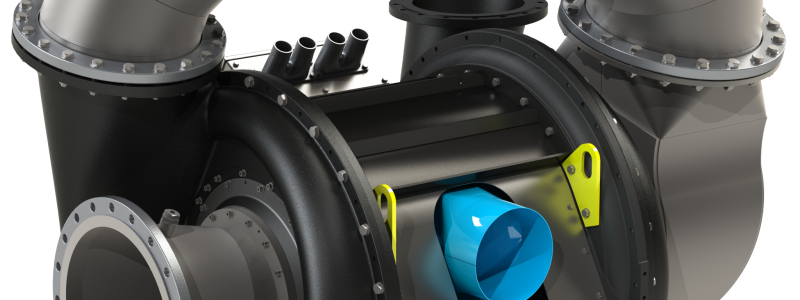

The product and solution offering provided by Metso to the corrugated industry is extensive. For example, Metso IQ Moisturizer corrects the warp of combined board by spraying a fine mist on it in a controlled way in the machine direction. Metso IQ Steam Profiler improves glue penetration and bonding as well as increases machine speed, especially with high-grammage virgin fiber liners. The Metso IQ Measurement family provides the most accurate real-time process information, which can be integrated into the process controls.

To support and strengthen its entrance into the corrugated industry business,Metso has signed a cooperation agreement with Ram Peleg of RPE Consult, based in Denmark. He has long experience in the corrugated industry, especially in sales, production management, machine performance improvement, online measurements and process control for corrugators, as well as from coaching and training corrugator crews.