Exclusive data from the new Smithers Pira report - The Future of Industrial Nonwovens to 2022 - reveals global sales of nonwovens for industrial applications in 2017 reached $20.9 billion. This is set to grow annually by 7%, across 2017-2022 reaching a value $29.2 billion in 2022.

Industrial nonwovens tend to be relative newcomers to industrial users, being employed to replace textiles, paper, polyurethane foam, fibreglass and plastics. The current generation of industrial nonwovens is higher-performing, more sustainable and more cost-efficient than the products they replace.

Smithers Pira pinpoints the key advances that are expected to aid market growth over the next five years:

Emerging markets

The industrial nonwovens market is becoming more global, as large new markets reach the degree of affluence needed to desire and afford the highest-performance products.

Large regions in the world - including China, India and Latin America - are upgrading infrastructure and adding both commercial and residential buildings. This requires industrial nonwovens, resulting in high growth rates.

These regions have intermediate levels of industrial nonwovens market penetration. Restricted by population size or per capita income, these markets are still growing at a respectable rate, often two to three times the growth rate of the mature markets. These markets are not as affluent or as sophisticated as the mature markets. They tend to support lower-technology products.

Industrial Nonwovens

Supply and demand and pricing trends

Supply and demand plays a major role in both the use and cost of industrial nonwovens. Industrial nonwovens, as opposed to consumer products, are primarily chosen on the cost-effectiveness of the material.

North America is a major oil producer and could soon be a net exporter. This suggests that petroleum supply will continue to exceed demand and that fibres and polymers based on petroleum will remain relatively stable. Spunlaid nonwovens would be most favoured by this trend, while almost all other nonwoven types would benefit to some extent.

Wood pulp is another key basic material for industrial nonwovens. Large expansions of pulping capacity have been made and more are planned. Pulp companies have managed the latest influx of new capacity better than in the past, and have successfully maintained prices at high but stable levels for several years. This suggests that wood pulp will remain more stable than historically, but at a higher price.

Industrial nonwovens supply and demand should remain well supplied through 2022 and should not see any significant price increases.

Sustainability

Environmental responsibility has become a market driver for nonwovens in recent times, due to a combination of regulatory pressures, consumer desires and retailer proactivity.

Wal-Mart has been an early adopter of tackling sustainability issues. In the mid-2000s, it announced a unilateral implementation of environmentally friendly policies and in 2006 unveiled a sustainable packaging scorecard, which suppliers were required to provide data for. There were metrics to determine performance and compliance, and there were results to compare against other suppliers. Wal-Mart promised to reward its best suppliers. The suggestion that the world’s largest retailer might judge and select nonwovens based on environmental performance of the suppliers has an immense effect.

Additionally, consumers have made it clear to their governments that they want to see progress towards reducing greenhouse gases and preventing global warming. These same consumers prefer that their governments regulate industrial polluters first and most energetically. Many current and projected regulations coupled with potential consumer rewards will make environmentally friendly manufacturing and products more profitable.

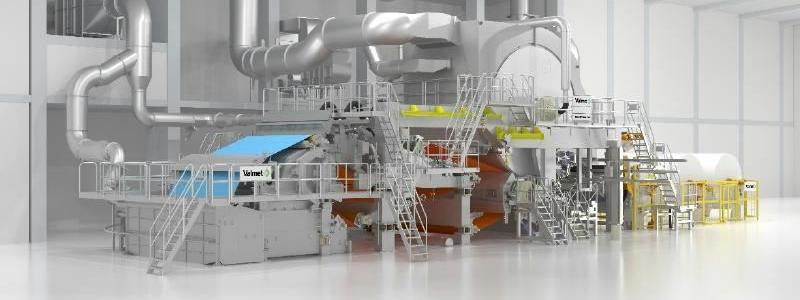

Manufacturing and capacity developments

Industrial nonwovens processes are usually based on newer technologies that tend to use less energy, produce less waste and require fewer raw materials. Most nonwoven processes have little or no waste, compared to textiles or paper. Nonwovens processes continue to evolve to make lighter-weight products, with lower energy consumption and reduced waste.

The ability of many industrial nonwovens processes to rapidly and inexpensively change from one product to another has allowed much greater product diversification than with woven or other materials.

The spunlaid nonwoven process has the shortest learning curve and large markets; significant new high-capacity volume has been brought on-stream in the last few years and is continuing. Much of the new capacity is being added in Asia.

Needlepunch, carded and wetlaid nonwovens are slower processes with smaller markets; capacity here is sufficient and being added at a much slower rate than for spunlaid.

Disruptive technologies

There are several new technologies that are significantly impacting the nonwovens market, however the three main developing areas include:

- Nanotechnology: This has wide potential, from nanofibres making nonwovens ultra-lightweight, to nanoparticles absorbing excessive amounts of liquids and gases

- Recycling: This has already made an impact in raw materials for nonwovens. There is already recycled cotton and polyester fibre used in industrial nonwovens

- Composites: These are becoming more and more sophisticated as laminates with stretchable nonwovens and films already in use.

Competitive materials

Nonwovens compete primarily with textiles and paper. Nonwovens are usually lighter-weight and lower-cost than textiles. Weaving and knitting are much slower processes than most nonwoven processes, making most textiles more expensive. Textiles are more durable and can be reused. Such reusability often requires laundering or some treatment, which can add cost and complexity.

Nonwovens are usually thicker, stronger and more absorbent than paper. Paper is lower-cost and disposable. While nonwovens can incorporate many different fibres and form three-dimensional structures, paper is very limited in both fibre choice and structure.

The Future of Industrial Nonwovens to 2022 is based on an in-depth combination of primary and secondary research. For more information on this market leading research, download the brochure here.