By Sara Giunchi, Communications&Marketing Oradoc

The Spanish paper mill of a global leader in sustainable paper and packaging – operating in 40 countries with over 500 packaging converting operations and 59 paper mills – faced challenges with their existing drying and doctoring systems, leading to contamination and quality issues in the final product.

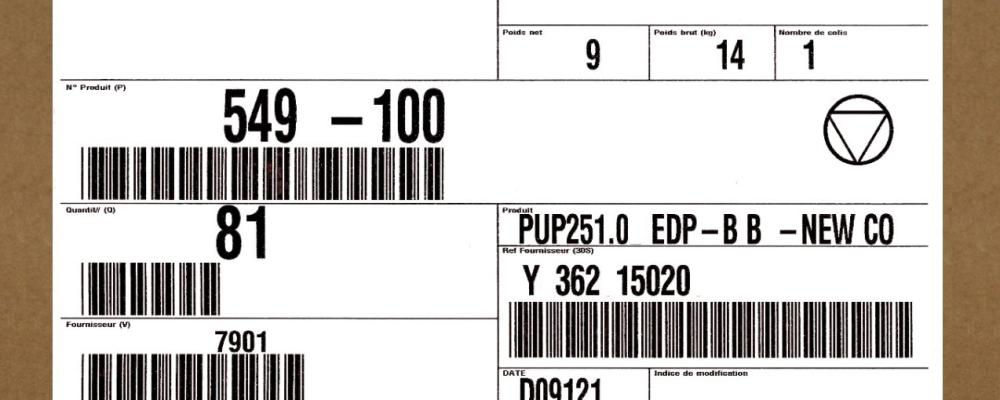

Here the main features of PM1: driers’ face mm. 2465, producing coreboard with a base weight of 200 – 620 g/m² at a max speed of 800 m/min.

The production process highlighted two main initial challenges:

- contamination from residual paper dust: accumulation of paper dust and residues on the doctor blade's bevel were subsequently transferred onto the paper, contaminating the final product. This contamination resulted in frequent maintenance interventions and a reduction in paper machine efficiency and quality of the paper produced

- ineffective cleaning mechanism: the paper machine's dryer cylinder, equipped with an outdated gravity-type rigid doctor with electromechanical oscillation, was unable to ensure optimal cleaning of the drying surface, negatively impacting the quality of the finished product.

Oradoc's turnkey solution

After a thorough analysis, Oradoc developed and implemented a comprehensive “turnkey” project, which included site surveys, doctor’s design, and installation of advanced technologies. The key solutions provided were OraFlex™ - as flexible doctor blade holder – and OraDust™ - as integrated dust removal system, which is also Oradoc’s newest product.

OraFlex™ is a flexible blade holder specifically designed for paper machines, ensuring optimal cleaning even under challenging conditions; it is ideal for critical positions such as presses, breast rolls, first and last dryers, calenders and pope reels. The OraFlex™ system, featuring a flexible DST blade holder, was introduced to adapt more effectively to the dryer surface; this flexibility improved doctoring efficiency and increased the cleanliness of the surface.

OraFlex™ guarantees uniform pressure distribution along the roll's surface without the need for profiling, a great pneumatic oscillating capability to enhance cleaning efficiency.

Suction box activity with machine running. Photo: Oradoc

A more modern pneumatic oscillation system (developed by Oradoc) was designed to replace the outdated electromechanical one, in order to provide consistent and controlled oscillation to the doctor blade, ensuring effective cleaning and residue removal. This new solution ultimately resulted in reduced wear on components and improved overall system performance.

Main benefits include improved cleaning performance and enhanced paper quality.

OraDust™ is the latest Oradoc’s product: a dust removal system integrated onto the doctor beam, connected to a custom-designed suction system. It effectively removes paper dust and residues from the doctor blade's surface, preventing contamination during the drying process, thus enhancing cleaning efficiency, improving product quality and minimizing maintenance needs.

The system is composed of a dedicated suction box made of stainless steel connected (through a special high-temperature resistant tube) to a suction mouth along the entire length of the blade.

The sizing and design allow for an optimal setup both in positioning (distance between the suction slit and the bevel of the blade) and ergonomics, minimizing total space, thus avoiding issues during normal production.

OraDust is connected to a dedicated suction system (in this specific case) composed of piping, filtration, and a dedicated fan. The sizing has been conceived in accordance with the customer, allowing for it to be used also for the installation of two additional OraDust units on subsequent dryers.

Suction control can be adjusted through DCS, in order to increase or decrease the suction flow, thus improving efficiency.

The installation, set-up and commissioning of the new systems were carried out under the supervision of Oradoc's technical team, ensuring seamless integration and optimal performance.

A short breakdown of goals achieved

- enhanced paper quality: better cleaning mechanisms led to higher-quality paper with fewer defects.

- increased operational efficiency: modernized systems reduced downtime and maintenance requirements, improving the overall drying process

- cost savings: by reducing waste and improving operational efficiency, the customer achieved a reduction in operational costs

- sustainability: enhanced cleaning and efficiency measures supported more sustainable production practices.

Oradoc's tailored solutions addressed the customer's specific challenges and long-standing issues of paper contamination, leading to significant improvements in product quality and operational efficiency. The integration of advanced technologies demonstrated Oradoc's commitment to innovation and excellence in the paper industry.