Runtech delivered a RunEco Vacuum System to Rondo, in Frastanz, Austria. The delivery included an EP600 Turbo Blower with EcoDrop Water Separator. In addition, EcoFlow Dewatering Measurement System with eight measurement points provides accurate real-time feedback about the dewatering performance and helps in determining the correct vacuum level and optimizing energy consumption.

Thomas Ogermann, operations manager for the paper mill, Rondo Ganahl Aktiengesellschaft, explains the decision: “We’ve put a lot of effort into the comparison between the vacuum systems on the market. There’s very limited space available for the integration of the new vacuum system into the existing paper mill. We decided to go for Runtech because of the very compact design and the complete scope of delivery, which reduces the number of interfaces for us. This gives us the possibility to perform the replacement of the existing liquid-ring pumps with the RunEco Vacuum System within a very short, planned maintenance stop.”

Benjamin Jentzsch, project manager for the project, adds: “Runtech’s project management and execution were professional, and all milestones were met on time. As we are dependent on a single turbo blower, it was very important that Runtech put a lot of effort into thorough testing during installation and commissioning before we made the final connection to the existing vacuum system. Thus, we were able to re-start after the planned maintenance stop without any delays or technical issues.”

Before installing the Turbo Blower system, EcoFlows were implemented to analyze the existing dewatering process. Even at that stage, additional water savings were observed thanks to smarter management of different water flows. The new solution was installed in parallel with the running machine, requiring only a small footprint. From the very first minute, vacuum levels were optimized, and the system now operates with significantly lower power consumption than guaranteed.

“Ourvariable-speed-controlled turbo blower allows the machine operator to select vacuum levels based on the actual need. With Rondo we gain another customer who is ready to challenge the ”status quo” regarding their current vacuum system operation. Reference visits to three near-by mills convinced the customer to go ahead with our state-of-the-art technology. The FAT test was successfully completed in Finland, with full communication in German due to the involvement of a German project manager, local partner Flowtec, and a German sales manager. The audit took place on January 2025, and the start-up followed on November 14, 2025, achieving an impressive timeline of just 10 months from idea to operation” says Jelle Schuivens, Sales Manager, Runtech Systems.

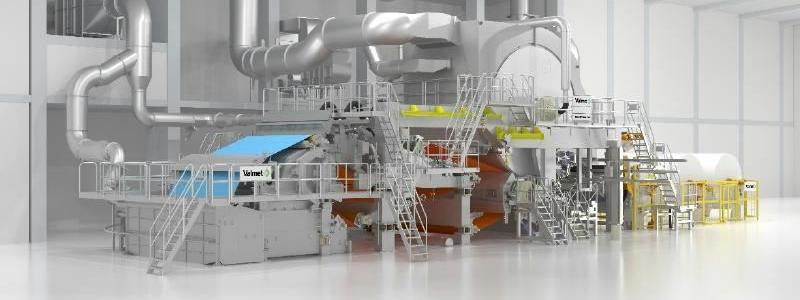

FAT is an important phase in any turbo blower delivery. By conducting FAT, both the supplier and the customer can be confident that the equipment will perform as expected once installed, ensuring a smoother and more efficient commissioning process. Photo: Runtech

Switching to EP Turbo Blowers is a gamechanger in energy efficiency. The variable speed feature of EP Turbo Blowers offers seamless optimization capabilities, allowing for an effortlessly fine-tuned vacuum system that surpasses the operational efficiency of standard offerings.

Benjamin Jentzsch from Rondo Ganahl received an EP Turbo-sign from Jelle Schuivens, Runtech Systems, to celebrate the project. The team was photographed during the kick-off meeting: (from the left) Martin Egger, Rondo Ganahl, Sören Siebrecht and Marcus Glaser from Runtech Systems, Andreas Schober, Flowtec Industrietechnik GmbH, and Helmut Kremsbrucker from Carantec Engineering GmbH. Photo: Runtech

Incorporating advanced blowers with integrated high-speed motors governed by frequency converters, EP technology enables meticulous control over the rotational speed and vacuum levels, tailoring them to the nuanced needs of the papermaking process. EP Turbo Blowers are designed to adapt swiftly, avoiding the inefficiency of throttling and minimizing air losses.

About Rondo Ganahl Aktiengesellschaft

The Ganahl Aktiengesellschaft is an Austrian family firm, steeped in tradition, that traces its roots as far back as 1797. The business is centered around the manufacture of corrugated board packaging products, corrugated case material and the collection of paper and packaging. Rondo paper mill in Frastanz in Vorarlberg (approx. 1.5 h west of Zürich), produces 135,000 tons of high-quality testliner products (white and brown) from 100 % wastepaper annually.