Mondi, a global leader in packaging and paper, has developed an innovative banana box packaging solution that is lighter though equally strong and more sustainable - thanks to close collaboration with partners across the value chain.

The project began when Mondi’s technical team for containerboard explored a simple but ambitious question during a customer visit in Latin America: Could the standard banana box be made lighter and more sustainable without compromising on strength?

What followed was an international collaboration between Mondi, trading partner Europcell, Ecuadorian banana exporter Incarpalm, and a leading European importer. Together, the teams redesigned the structure and paper composition of the traditional banana box, testing multiple scenarios to balance durability, weight and humidity resistance.

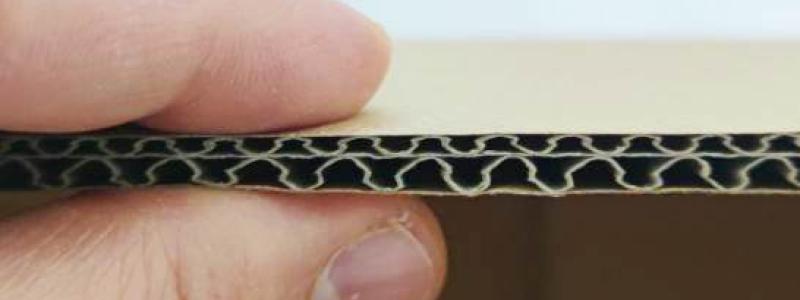

The new concept combines ProVantage SmartKraft Brown, known for its high strength and protective qualities, with ProVantage Frescoflute, a semi-chemical fluting that enhances firmness in lightweight packaging boxes. The result is a box made with around 40% recycled fibre and up to 10% less weight than the previous design - helping to lower emissions during transport without compromising fruit protection.

To validate performance under real-world conditions, a full-scale production trial took place in Ecuador in summer 2024. Bananas packed in the new boxes were shipped to Europe over a 33-day journey, with sensors monitoring humidity and temperature. Despite extreme humidity levels of up to 100%, the boxes maintained their integrity throughout transit.

“Seeing the new box perform under such tough conditions was incredibly rewarding,” said Marek Motylewski, Technical Service Expert for containerboard products. “It started as a question on a customer visit and turned into a solution that delivers measurable benefits for the entire supply chain.”

“The reliability of the box is everything,” added Jorge Romero, Operations Manager at Incarpalm. “This collaboration proves that innovation and practicality must go hand in hand.”

The success has already sparked interest among other fruit exporters and retailers. With upcoming regulations, including a 2026 EU ban on plastic wrap inside banana boxes, demand for fibre-based alternatives is expected to rise.

“This project shows what’s possible when we combine technical expertise with open collaboration,” said Gijs Huisman, Sales Director at Mondi Containerboard. “It’s a great example of co-creation that delivers tangible results in strength, sustainability and supply chain efficiency.”

The improved banana box marks another step in Mondi’s commitment to developing fit-for-purpose packaging that meets customer needs while supporting more sustainable solutions.