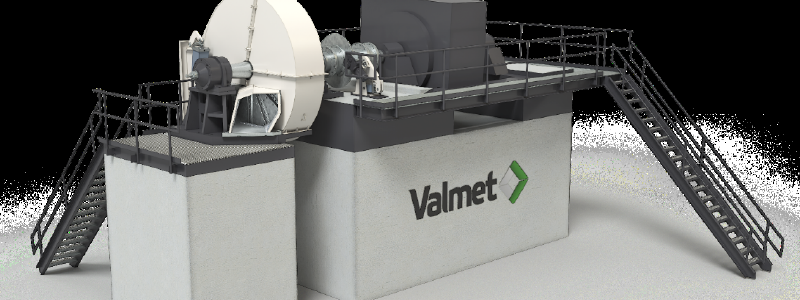

In April, De Iuliis C & A successfully completed the first phase of the major modernization project at the San Martino Paper Mill, on schedule. This milestone marks a critical step within the broader multi-year intervention on the historic Broccostella (FR) facility, highlighting both the strategic value of the initiative and De Iuliis’s technical expertise in executing complex upgrades in the paper manufacturing sector.

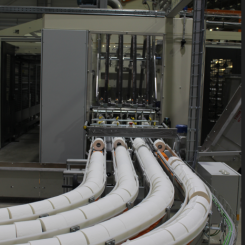

This initial phase, a key component of the overall revamp plan, involved the construction and installation of a new calender, pope reel, and the SilentDrive system in the after-dryer section. The work was completed ahead of schedule, finalizing one day earlier than planned.

Technological Innovation and Measurable Results

The installation of the new calender, pope reel, and associated auxiliary systems has yielded immediate and tangible benefits:

· Enhanced Finished Reel Quality: The new calender provides uniform and consistent pressure on the web, improving sheet smoothness and surface appearance—enhancing the final product's perceived quality in the market.

· Improved Winding Performance: The new pope reel reduces winding defects, delivering more compact and higher-quality reels.

· Optimized Paper Tension Control: The SilentDrive system enables more precise control of web tensions throughout the production line, minimizing web breaks and defects.

· Advanced Machine Parameterization: Integration with new automation systems allows for real-time control of key operational parameters, improving process stability and reducing product variability.

Safety at the Core of the Project

A primary objective of this phase was to enhance operator safety. All installed components were designed with a focus on ergonomics and personnel protection. The new solutions allow operators to monitor and intervene in the production process while maintaining a safe distance from rotating components. Additionally, localized cleaning and scheduled maintenance operations are now easier and fully compliant with current safety regulations.

One of the most significant achievements in this phase was the overall improvement in workplace safety. Through the introduction of updated safety systems, reconfiguration of access points, and installation of new safety barriers, operational risk during routine tasks has been substantially reduced. Operators now work in a more controlled and secure environment. These upgrades not only comply with the latest occupational safety standards but also set a new benchmark for similar facilities.

Efficient Project Management and Next Steps

Completing the first phase ahead of schedule demonstrates De Iuliis’s organizational efficiency and its ability to manage every project stage—from design to commissioning—with precision.

With this milestone achieved, the project now progresses to the next phase, which will involve further critical sections of the paper machine, including the press section and pre-dryer section. The goal is to further increase production capacity, reduce energy consumption, and enhance the environmental sustainability of the facility.

A Strategic Project for the Mill's Future

This multi-million-euro revamping plan is aimed at ensuring the long-term efficiency and competitiveness of the paper machine. It is a strategic investment that strengthens the San Martino Paper Mill’s position in the European paper industry, at a time of increasing demand for high-quality, environmentally sustainable paper products.

The successful completion of this initial phase also reaffirms De Iuliis’s reliability and engineering competence, confirming its role as a key technology partner for the paper industry and a leading player in production plant modernization.