Kadant Lamort SAS, a subsidiary of Kadant Inc., and Unikpakhellas S.A., an affiliate of Invdeco Group, are implementing a new stock preparation system that yields high-quality paper from a wide range of materials while reducing fiber loss and freshwater consumption.

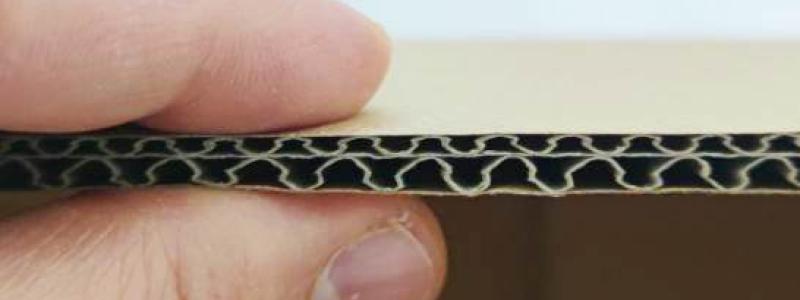

Unikpakhellas selected a comprehensive Kadant service package that includes engineering, erection supervision, commissioning, training, and start-up assistance. The system will process a wide array of materials from local OCC and mixed waste to high-quality OCC, including materials that can be challenging to treat in stock preparation. The new line will have the capability to produce a variety of grades including polyethylene-coated paper.

In addition to revamping UNIPAKHELLAS’ current stock preparation line, Kadant Lamort will install the Heli-Drum™ system into a new stock preparation line to process the wide range of raw materials. Kadant Lamort will also supply an approach flow system including Radiclone™ hydrocycling system with high-efficiency contaminant removal to obtain high-quality paper for top-ply, as well as Periscreen-M™ machine screens. A Rotoflex™ recovery strainer will help reduce freshwater consumption, and a screw press reject compactor will contribute to disposal cost reduction. Kadant Lamort will also implement two intelligent, adaptive technologies, BoosTEK™ and FiberNet™, to assist UNIPAKHELLAS’ plans to reduce energy costs and improve fiber recovery.

Kadant and INDEVCO Group have collaborated for over two decades, implementing many successful recycled paper operations in Lebanon and Egypt. “We're committed to offering our customers tailor-made solutions to minimize fiber loss and provide sustainable processes,” stated Marcello Giorgi, global sales and marketing director at Kadant Lamort. “Our relationship with INDEVCO allows us to implement cutting-edge technologies that advance the pulp and paper industry.”