Fortress Paper Ltd. has elected to provide a general corporate update relating to its operations.

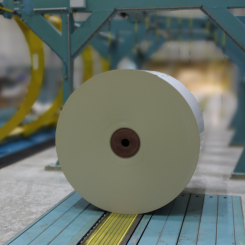

Fortress Specialty Cellulose Mill The combination of short supply and strong demand for dissolving pulp has created a robust market. Along with recent announcements of increased capacity in dissolving pulp from conversions and brownfield projects, there have also been corresponding announcements of additional viscose staple fiber capacity. The Company believes that it is well positioned to benefit from the expected timing of completing its conversion at the Fortress Specialty Cellulose Mill to produce dissolving pulp within the next five months. This timing should allow the Company to benefit from the current robust dissolving pulp market as compared to other conversion projects which typically take 18 to 24 months to complete. The Fortress Specialty Cellulose Mill currently produces NBHK and production volumes have been pre-sold through to the expected conversion time. Dresden Mill Demand for our non-woven wallpaper base remains strong and the Company’s Dresden Mill currently has an order book of approximately 8 weeks. The Company’s 2011 capital expenditures program at the Dresden Mill includes a Euro 3 million upgrade to increase capacity. Upon completion of the upgrade, the maximum speed of the paper machine should be increased to 450m/min which equates to a potential annual capacity of approximately 55,000 tonnes of nonwoven wallpaper base. This would represent a 15% increase from our current production capacity of 48,000 tonnes per year. Fortress Paper continues to seek opportunities to expand its production capacity of non-woven wallpaper base. Landqart Mill The Landqart Mill recently completed its paper machine no.1 ("PM1") rebuild to produce banknote and high security papers. The enhanced PM1 allows the Company to consolidate banknote and high security papers production on PM1 and significantly improve overall production efficiency. By consolidating production of bank note and security papers into PM1, the Landqart Mill intends to temporarily suspend the commercial operation of paper machine no. 2 and utilize it only for trials and sample production until such time as this additional capacity is required. This plan to improve our production efficiency has resulted in a reduction of our overall labour requirements. This reduction will mainly affect production staff, however there will also be a reduction in administrative and middle management personnel. Fortress intends to downsize the work force at the Landqart Mill by approximately 40 to 60 employees. The Company believes that the streamlined labour costs and improvement in production efficiency will partially offset increased cotton costs and address some of the challenges resulting from a current over capacity due to the postponement of implementation of several major currencies including the new Euro2, Swiss Franc and other banknotes.