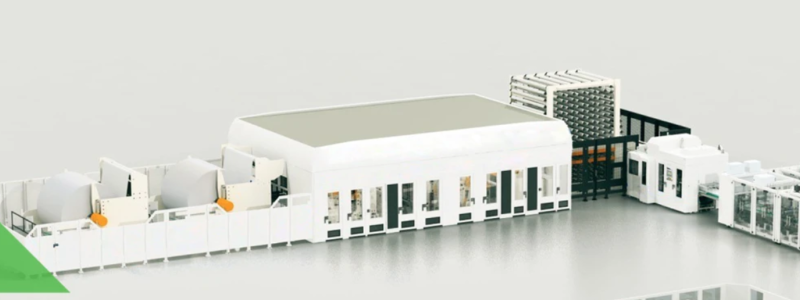

In June, E.C.H. Will introduced its new Technical Improvement Program (T.I.P.) for converting machines. A highlight of this new program is T.I.P. E 1530, a module that enhances product flexibility of converting machine types 280 – 282, Alpha and 280 Delta by integrating an additional infeeder.

Basically the original machine configuration determines the possible product range of a customer. But consumer demands change; new products are in demand today. "This makes product flexibility essential", says Klaus Dammann, Product Manager Technical Rebuild at E.C.H. Will. "When the customer wants to maintain and strengthen his position in the market he is forced to modernize."

The T.I.P. E 1530 additional infeeder is one element for this purpose. A completely new infeeder is integrated into the existing machine. This additional infeeder unit enables extensive new combinations of cover sheet and supplementary sheet, hence numerous new product variations. Different inserting programs such as mix and non-stop operation can be selected. Non-Stop operation enables continuous production and thus an improvement of product efficiency, as less start-up waste is produced. During mix operation design options with colored cover sheets are at the center of focus. Of course it is also possible to add a sheet with advertisement under the cover sheet.