Varel Paper and Board Mill has awarded Voith Paper with a very sophisticated project. Besides increasing production capacity and extending the product range of PM 4, the focus is on efficient energy use and environment-friendly paper production.

The company, domiciled in Varel, Germany, currently produces corrugating medium and testliner in a basis weight range of 120 to 220 g/m2 on its PM 4. Before the turn of the year 2010/11, an extensive rebuild and maintenance program will be launched. The capacity of PM 4 will be increased to 300,000 t/a and in future, about 50 % of its production will be white liner grades.

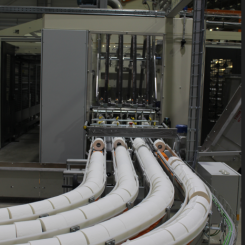

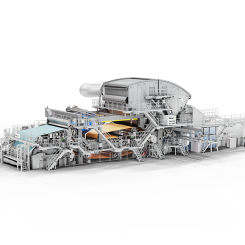

Because of the additionally required raw materials, the rebuild comprises a major extension of the stock preparation system to three lines, for which Voith will deliver the crucial equipment. PM 4 will undergo complete modernization. For instance, the paper machine will be equipped with new approach flow systems, the headboxes will be renewed and both fourdrinier wires will be extended. A DuoD hybrid former will be installed for the back ply, while the top ply will be equipped with a DuoShake unit.

The dryer section will be completely renewed, and a SpeedSizer film press including non-contact web drying will replace the old unit. In addition, PM 4 will receive a new soft calender and a MasterReel unit. On the winder, a new unwind station for larger parent rolls will be installed.

Voith Paper Automation is responsible for the complete modernization of the paper machine control system.

A particularly interesting aspect of this rebuild is the working width of the new components, which will be widened from 5.1 m to 5.3 m, thus making way for the future.

Varel Paper Mill takes on the enormous job of engineering and planning and will be assisted by Voith Paper. Start-up of PM 4 is scheduled for mid-February 2011.

With this rebuild, Varel intends to achieve considerable energy savings. Environmental aspects are in the focus nowadays: Varel wants to produce environment-friendly products as resource-conserving as possible. The target is to significantly reduce CO2 emissions throughout the paper production process.

American Packaging Corporation (APC) is showcasing its RE™ Design for Recycle High Barrier Paper pouch...

Tissue World Miami, North America’s largest and most influential tissue exhibition and conference is back...

Following the recent liquidation of French recycled containerboard producer Wizpaper, another French paper manufacturer, Gemdoubs...

Lessebo Paper announces that Ebba Ingvarsson has been appointed Chair of the Paper Profile Steering...

Algerian tissue producer WARAK, a subsidiary of the Faderco Group continues partnering with Valmet by...

The global environmental non-profit CDP has published its annual A Lists, recognising companies for leadership...

UPM has reaffirmed its leading position in sustainability by achieving leadership-level scores in the 2025...

The Guillin Group, European leader in food packaging solutions and related materials, announces that its...

One.five, a Hamburg-based provider of sustainable packaging solutions developed using modern AI technologies, is enabling...

Bain & Company today released new research showing how paper and packaging companies are responding...

The strategic partnership agreement between UPM and Versowood, announced in September 2025, has received the...

Job listings