Vishay Intertechnology has announced that it has received a second order for its Reel Optimizing System for paper manufacturing from COMECART, a subsidiary of Burgo Group, one of Europe's largest producers of graphic papers for printing.

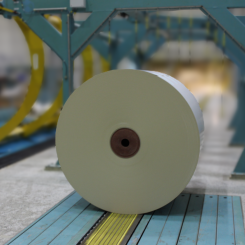

Vishay's Reel Optimizing System was installed in October 2008 on the Verzuolo mill paper machine number 8 off-line coater reel. The Vishay system was part of a new reel supplied by COMECART. The new reel has a trim width of 6.4 m and a maximum speed of 1,400 m/min and can wind spools with maximum diameter of 3 m.

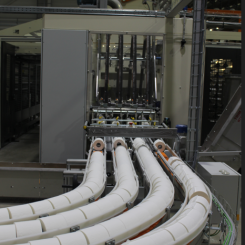

The second Vishay system is a retrofit to the existing reel of paper machine number 3 at the Duino mill. The system is scheduled for delivery in the first quarter of 2010. (Vishay Measurement Group GmbH)

Vishay's customized Reel Optimizing System reduces paper scrap during the reel change-over process and controls the paper roll density throughout the entire reel winding process. Measurement and control of the nip force is accomplished by using strain gage-based custom load cells together with hydraulic cylinder force and position control system. Dedicated software allows continuous analysis of the nip force and roll density throughout the reel change-over and winding process. The relevant process data is stored for additional future studies.