BillerudKorsnäs in Gävle has invested large amounts over a long period of time, to better both externally and internally. The investments has led to an improvement in productivity as well as environmental enhancement, and there is more to come.

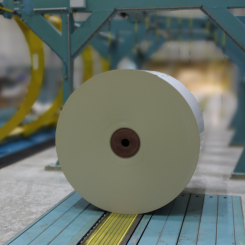

The company has roughly invested 2 million SEK a day since 2010, regarding productivity- and environmental enhancing measures. The latest investment is regarding PM 4, the machine that manufactures portion packs, which will mean an increase in production as well as a more even quality.

-To our customers the main concern is that the product holds the same quality and with the improvement of PM4 we are able to meet their demands. Since every fourth portion pack in the world comes from our productionline, the demand for quality is naturally the biggest factor, Magnus Kangas, head of BillerudKorsnäs Papermill i Gävle, states.

According to Mister Kangas, there will be an increase in production of about ten percent, when bottlenecks are eliminated. At the same time, BillerudKorsnäs invests in a facilty for heatwaste, which means that the papermill continues to support the inhabitants of Gävle with distance heating:

– We are a big supplier of distance heating to the people of Gävle, our part is approximately half of the total production. During the warmer parts of the year, this means that it is our deliveries that provides the city with heating.

Besides the latest investment, the upgrades of recent years has meant that the company has replaced the evaporator, made investments in a new furnace for biofuel and upgraded the heat exchanger for drying. There has been focus on environmental improvements and the company has reduced the use of oil with about 90 percent, from 45 000 cubic metres to less than 5 000 cubic metres of oil.

– It is a double gain, for the environment and for us. Solely, the improvement in new heat exchangers has led to our entire conty meeting the carbondioxide target. And futher more, we have reduced our external dependency for electricity, Magnus explains.

What makes all the improvements even more sophisticated is the fact that now there are three different parties involved in the same industrial area. The new biofuuel furnace is a joint venture between BillerudKorsnäs and Gävle City, a separate company, and with the sale of PM2 to Swedpaper there is a third party on the same compound. And Magnus Kangas has been an eyewitness to all the improvements.

– The three parties share steam, electricity and pulp. It is an old an traditional industry tats undergoes great change and we don´t solely invest in machinery. We have undergone organisational changes, making all employees take more responsibilty and the separate work teams play a bigger part, where the operators is a crucial part of the development process. We work with key performance indicators and we reached an All Time High during 2013. So far, we are meeting the budget for 2014 which indicates that it will be an even better year.