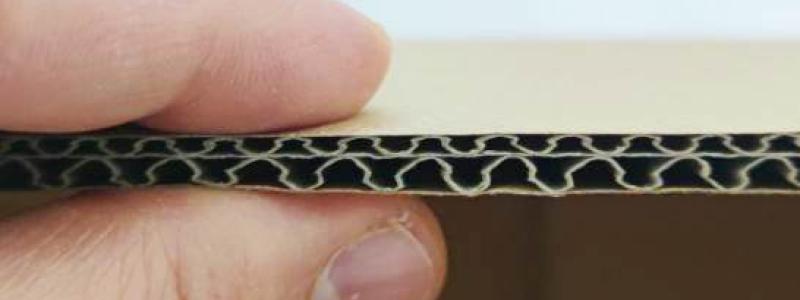

High-volume digital printing on corrugated board is now becoming a reality, this was confirmed at a workshop organised by FEFCO last week, the European Federation of Corrugated Board Manufacturers. This technology opens up wide new possibilities for maximising the use of packaging as a platform for communicating directly to consumers.

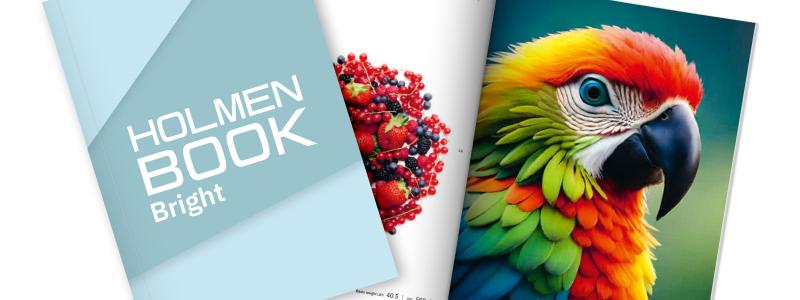

With digital printing, corrugated board is being transformed from packaging and protection to a new marketing communications medium, thanks to striking print quality, and the possibilities for customisation and creativity in design. "It is a real revolution," said Angelika Christ, FEFCO's Secretary General. "Now, with corrugated packaging, the medium really can become the message".

At the same time, digital printing allows fuller use of new technologies such as QR codes and augmented reality (AR), enhancing the customer experience by making the packaging interactive. One example: Prospective customers for LEGO can scan the box and AR will bring the contents of the box to life on a screen. And along fragmented supply chains, unique QR codes printed on packaging are helping to share data.

Until now, the technology for digital printing on corrugated board has been mainly used for display POS and short-run samples. But this one-day seminar, “High Volume Digital Printing on Corrugated Board”, showcased how leading printer manufacturers can now produce high-volume, high-quality and competitively priced digital printing on corrugated board. New digital printing equipment was presented by ESKO, BOBST, Hewlett-Packard, Sun Automation, Barberan and XANTÉ, all capable of transforming corrugated board into customised and customer-oriented packaging and displays.

The demand for digital printing mainly comes from the customers, packers & fillers and from retailers. The need for versioning and personalisation, regional marketing, last-minute changes, rapid response to customer demand and accelerated time to market are the principal factors pushing the industry to move from analogue to digital printing.

As Angelika Christ reported, the federation was extremely pleased that so many companies joined this event, thus demonstrating that FEFCO continues to offer a useful service to its members. Once more, FEFCO has shown its ability to share knowledge and facilitate the spreading of information at European level.

Wilbert Streefland, the consultant who co-chaired the seminar, quoted Charles Darwin “It is not the strongest industry that survives, but the most adaptive”. This workshop demonstrated clearly that the digital printing market will provide huge opportunities for adding value to corrugated packaging and competitiveness. Now is the right time for FEFCO members to take advantage of these opportunities.

The challenges that this technology is also overcoming include ensuring brand colour consistency with digital print. But some of the challenges have to be met by changes in working pattern too - and notably by workflow automation. Digital print makes more numerous but shorter print runs possible - responding to the changing dynamics in fast-

moving consumer goods markets. This gives rise to greater administration and re-organising the prepress work. According to Marc Van Damme, FEFCO Production Committee Chairman and Chief Technical Officer for VPK Packaging Group: “It’s not just about switching to digital, it’s about rethinking your work process”.

"Digital printing on corrugated board is no hype - it is a solution ready for use in everyday production," concluded Angelika Christ.