PT Sun Paper Source in Sukoanyar, Indonesia, has successfully put into operation its new VTM 1, a tissue machine from Voith. The operating speed of 1,600 m/min was reached three days after start-up.

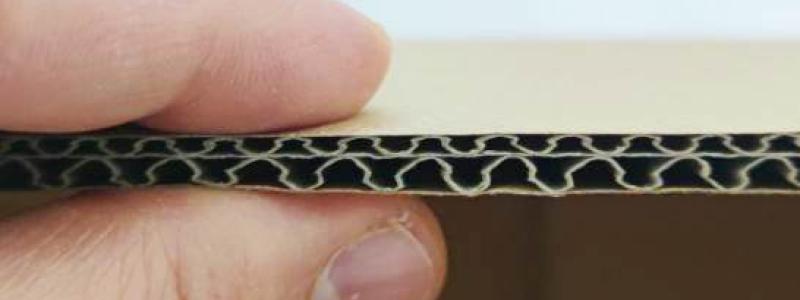

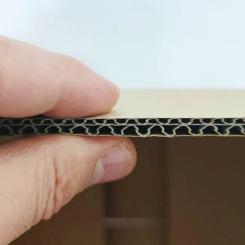

It is the first machine in Asia to feature a NipcoFlex T shoe press combined with a steel Yankee cylinder and a steam heated high-performance hood. With this project, Voith has thus succeeded in further strengthening its position with innovative technologies for the tissue sector.

The delivery included the approach flow system, the vacuum system, the VTM 1 tissue machine with a wire width of 2,860 mm, together with auxiliary equipment, MCS, DCS and QCS. The VTM 1 is based on a modular concept that in this case consists of a single-layer MasterJet Pro T headbox, the NipcoFlex T shoe press, a 16-foot steel Yankee cylinder, a high-performance hood and the MasterReel winder.

The VTM 1 with shoe press, steel Yankee and high-performance hood from Voith is a very energy-efficient design. It allows high operating speeds and problem-free operation. In comparison with conventional press rolls, the dry content after the press with NipcoFlex T technology is up to 5% higher. That means that up to 20% of the thermal energy can be saved.

In order to be able to even better support Asian customers on site, Voith manufactures Yankee cylinders made of steel and Yankee hoods in China. Quicker local support is ensured by a competent team on site for all questions regarding tissue production.