Honeywell announced recently that it has been selected to provide the process control system for a new pulp mill under construction in the Chita region of southeast Russia – the first greenfield pulp mill to be built in Russia in 35 years.

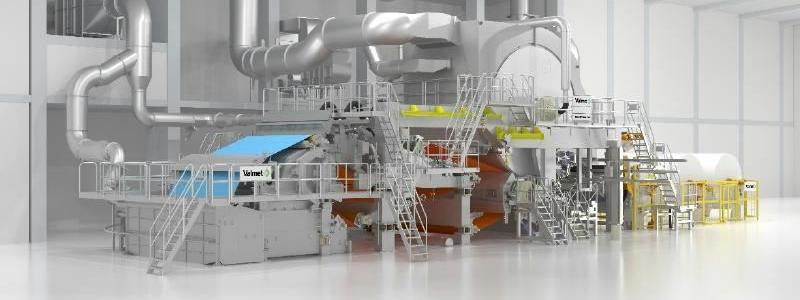

Built and operated by Russian North Star Pulp Industrial Complex LLC, but wholly owned by Chinese firm Heilongjiang Xingbang International Resources Investment Co. Ltd., the new pulp mill will use Honeywell's Experion Process Knowledge System (PKS) to run plant operations. The new mill will have an annual capacity of 230,000 tons of unbleached market pulp when fully operational. Start-up is expected in mid-2015.

The entire output of the mill will be exported to China to meet the growing demand for paper goods there, including construction material, packaging and other products. Consumption of paper-based goods in China continues to rise at a rate of around 10 percent a year and is expected to reach 115 million tons in 2015. The new pulp mill project is one result of efforts for greater cooperation between Russia's Chita region and the neighboring Heilonhjiang province of China.

"Having efficient control systems in place helps improve production performance several times over, so we put a great emphasis on choosing the right ones. Honeywell's Experion PKS fully meets our requirements in terms of energy efficiency, reliability and safety," said Yang Guangwen, chief engineer and vice general manager, North Star Pulp Industrial Complex LLC. "In addition, Honeywell has offices in Siberia and in China, which will make our collaboration easier."

Honeywell's Experion PKS will be installed in all of the mill's major process areas including wood preparation, pulping and drying, as well as the chemical recovery and combined heat and power plant.