Aveva announces that Centroprojekt, an engineering company specialising in water, air and solid waste treatment solutions, has selected Aveva PDMS software for basic engineering and detailed design on major projects including a large pulp & paper plant, and a thermal power station.

"One of the main advantages of Aveva PDMS is the ability it gives us to customise the 3D models so precisely that we can create very accurate virtual reality scenarios to optimise our design,” said Jean Carlos Pontel, engineering manager of Centroprojekt, “This helps us to eliminate potential conflicts between the different engineering disciplines, reducing rework in the later stages of the project. Aveva PDMS also helps us to allocate our resources in a more effective and economical way.”

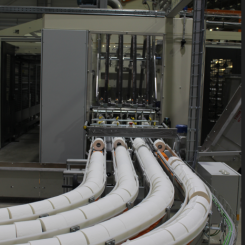

Centroprojekt first used Aveva PDMS for detailed design in the construction of Brazil’s largest pulp & paper plants. To gain maximum benefit from the new technology, a series of training sessions were held in collaboration with technical staff. “We have seen a big gain in our overall productivity,” added Mr Pontel. “The software is a knowledge multiplier, enabling our professionals to reuse their experience and project databases on future projects."

Centroprojekt’s use of Aveva PDMS on the pulp & paper plant project means it has reached the construction stage without encountering any problems.

Aveva PDMS is the most widely used software in Brazil for 3D modelling of industrial projects, particularly within the oil & gas sector. It is also used in Brazil by the country’s growing energy, pulp & paper and mining industries.