Voith has reworked and further developed the technology behind its VariFlex two-drum winder. Along with simplified operation, special attention was paid to ensure robust safety technology. The winders up to 7 m wide and with a roll diameter of 2,100 mm are the first components to come onto the market.

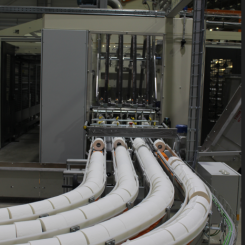

The Voith VariFlex winder is based on the two-drum concept. The roll set is wound in a roll bed formed by two winder drums. With the compact new VariFlex line, Voith has further developed its VariFlex S, M and L two-drum winders and simplified their control technology.

It is primarily the roll geometry, the roll arrangement and if applicable the covers that are important for the high productivity and consistent quality of the two-drum winder. Properly combined, they ensure high speeds, a reliable web run, good roll geometry and reliable handling of large roll diameters as well. Depending on the requirements and design, production speeds of up to 3,000 m/min are possible without any problem.

The modularly structured VariFlex was designed for a broad range of applications and due to different roll and cover combinations allows configurations for numerous paper grades. While new paper machines from Voith are already delivered with a winder, the new VariFlex was designed in particular for replacements or rebuilds on existing machines which requires only very short shutdown and optimization times.

Since VariFlex is directly delivered with all drives included, customers benefit from fewer interfaces and especially short commissioning and system optimization timeframes. The specifically developed elastic covers for the winder drums, ElaGrip and ElaCare, ensure flawless winding quality even for demanding paper grades. Together with the VariPlus and VariTop single-drum winders, VariFlex covers the entire range of winders for all paper grades and characteristics.