The new Metso Pulp Analyzer (Metso MAP) features the first on-line measurement of micro-scale details of fiber properties. It provides pulp and papermakers a tool that helps to predict how fiber properties will affect final sheet strength properties. The new analyzer also enables precise furnish preparation and low consistency refining management resulting in better sheet runnability, higher machine efficiency and lower furnish costs.

Metso introduces the next generation’s pulp analyzer (Metso MAP) that features a new high definition fiber imaging module. This module represents the first on-line measurement of micro-scale details of fiber properties, including fibrillation, vessel segments, flocs and other particles. The fibrillation measurement, combined with other fiber properties measured by the analyzer, can be processed in a modeling tool that helps to predict how fiber properties will affect final sheet strength properties.

This next generation’s analyzer provides online measurement of fiber dimensions including kink, curl, size distribution and fractionation. The Metso MAP has established an excellent reputation for measurement accuracy and reliability in the pulp and paper industry.

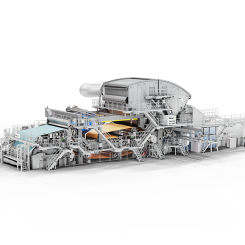

The new product is intended for managing fiber properties in papermaking furnish preparation as well as in mechanical, recycled fiber and kraft pulp mills. To provide the highest measurement application flexibility, the analyzer samples from up to 20 process fiber streams. This new analyzer also utilizes brand new manual sampling stations that can be located throughout the plant. To date, the product has been installed in paper, tissue and board mills.

With a freeness measurement module included in the same platform, the Metso MAP provides pulp and papermakers with a quickly updated and complete fiber and furnish measurement solution. More precise furnish preparation and low consistency refining management provides better sheet runnability, higher machine efficiency and lower furnish costs. Pulp mill operations will benefit from minimum shives in mechanical and chemical pulps, and reduced fiber quality variability. In addition to providing operators with an unprecedented window into pulp quality, these measurements are an integral part of pulping and refining controls.