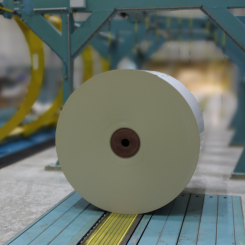

GL&V has been involved with the latest improvements at Ružomberok mill. As a part of the “White Rose” project the Celleco Twister hydrocyclone system was installed before the pulp drying machine.

The Celleco Twister was installed into the post cleaning stage before the pulp drying machine. When the hydrocyclone cleaning process is used conventionally before the drying machine, the pulp is run at fairly low consistencies. The pulp’s consistency is then raised afterwards to 1.5–2.0 % before it enters the drying machine. The Celleco Twister simplififies the cleaning process because the pulp is run through the Twister at higher consistencies and then run directly to the paper machine.

Mondi´s Ružomberok Mill in Slovakia, Mondi SCP, belongs to the Mondi Europe & International Division as a part of the Mondi Group. The Division has around 95 production plants in 30 countries and approximately 28,000 employees producing corrugated paper, bags and specialities and uncoated fine paper (UFP).

The modern history of pulp production in Ružomberok started in 1981 but capacity has risen from those days from 600 t/d to the current value of 1450 t/d of hardwood and 750 t/d of softwood pulp. Over this period, the equipment has gone through several technological modifi cations that have led, not only to increased production, but also to a significant reduction in the environmental load.

Mondi SCP has three paper machines with the total capacity over 180,000 tons of offset paper and 330,000 tons of office paper.

Mondi SCP is located in a mountainous area, in the northern part of Slovakia. The Váh river passes by the mill.

With the growing demand on the pulp market and demanding requirements with respect to brightness and impurities, one of the major modernizations of pulp production was launched in 2006. In 2007, a technology for pulp screening, before the drying section, was introduced, through which the mill managed to achieve standard quality in commercial pulp in terms of impurities. The extension of the bleach plant by a hydrogen peroxide (PO) stage, the “White Rose”-project, started up in 2007. On January 10 2008, the peroxide pulp bleaching technology was launched.

The major features of Celleco Twister are:

1. Up to 2% feed consistency operation with comparable cleaning performance in conventional hydrocyclones at 1%.

2. Superior cleaning performance over the entire operating consistency range.

3. Up to 50% lower applied energy.

4. Considerably lower reject rates than conventional hydrocyclones.

5. Celleco Twin Wall design.