ABB has won a contract to upgrade automation and production equipment at DS Smith Paper's Kemsley Mill in Sittingbourne, Kent, UK.

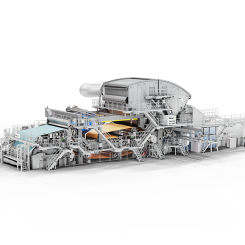

Included in the contract is the automation of a new stock preparation plant that is feeding recycled fibre to the mill’s PM6. This automation allows the mill to produce lighter weight packing materials efficiently to meet customers’ demands.

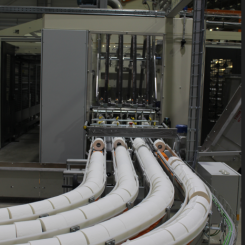

ABB is supplying a System 800xA extended automation system, upgraded from a version 3.1 to version 5. The delivery includes an Information Manager, OPC server, backup server, application engineering, commissioning and start-up services. Also included in the delivery is a third party IndustrialIT Enabled video surveillance system. The VidEOnet System allows operators and supervisors to observe the plant through the control system and office based PCs.

PM6 itself is also getting an upgraded quality control system as well as new drives and motors for its wire part and press sections, intended to increase the mill’s production by allowing equipment to run at higher speeds. The equipment is integrated with the mill’s existing systems through a drive system user interface.

The distributed control system of the filler plant and starch plant is also enhanced. The upgrades integrate operator, engineering and management information and the control system, with the paper machine and stock preparation process equipment. Integrating these systems saves the mill money and increases productivity.

ABB is adding an ABB ProfileIT Air-Water Profiler to PM6 to provide precise moisture profile control.

System software licences are listed under the ABB Sentinel subscription program, cutting the cost of managing the lifecycle and maintenance of the software.