There is an urgent need to create a new industrial paradigm in Sweden where not only environmental sustainability is safeguarded, but also new business models that secure long-term competitiveness. That is one of the key findings in the outlook report “The road ahead for Scandinavian industry”, published by Tieto and KTH today.

Digitalization is pressing on, customer demands are more challenging than ever and environmental concerns are calling for a re-organised approach toward industrial production. These challenges are top of the agenda for the Swedish industry today, and getting on-board with the new technology is a matter of survival. According to the new outlook report “The road ahead for Scandinavian industry”, published today by Tieto and KTH, achieving long-term competitiveness is well within the reach of all manufacturers, large and small – provided that action is taken now.

– In terms of digitalization, companies in process and discrete manufacturing need to act quickly to catch up with other business sectors such as telecom and retail. While this can be done in a relatively short time span, the goals and visions must be clearly defined. Replacing legacy systems is not just worthwhile but crucial for survival of the manufacturing industry, says Per Håkansson, Head of Manufacturing industry Sweden at Tieto.

Nine key trends in Scandinavian industries

In the report, Tieto and KTH identify that there are multiple drivers behind the new potential industrial paradigm, including intelligent products, new ground-breaking materials, the sharing economy and Internet of Things. Together, they lay the ground for nine trends that should lead to the rethinking of business models among Swedish industries:

- Scalable and mobile operations: New customer demands are steering manufacturers away from conventional high volume products towards scope-oriented products. The move to scalable, cost-effective IT systems and new business approaches does not only make strategic sense, it is a matter of survival. A highly likely consequence of this development is that the primary source of income for manufacturers will also change as they become far more dependent on a range of sub suppliers in different industry segments. In terms of operations at larger companies, having one main production site may well be a thing of the past.

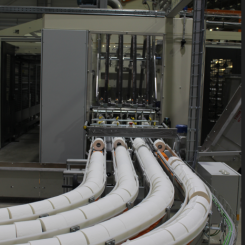

- The production shift. In the production systems of the future, machine automation and Plug to Order (PTO) modules will be key components. PTO refers to new ways of managing production without having to purchase equipment which is used and then discarded. Going forward, industrial machines will be leased or hired and will also reconfigure themselves autonomously. When the equipment has become fully outdated and irrelevant, only then will it return to the service provider.

- The coopetition effect. The principle of “coopetition”, a concept that was launched in the 1990s, is a method for bringing together companies with common interests to cooperate in order to attain a higher-value production. Recently, this method has proven to be very successful in helping to break new ground and to form solid working relationships that help companies to co-evolve in any given market sector. The coopetition effect is coming into full swing.

- Cloud manufacturing. With the rapid evolution of information technology, ways of thinking and conducting business in manufacturing have changed fundamentally. In order to cope with rising volumes of data and fast-changing customer demands, decision makers need to have constant access to the very latest data and reports from factory floors and other key sources. If applications and communications tools are lacking in any way, business will be affected. Consequently, more and more companies are recognizing the clear advantages of adopting a cloud-based platform as an integrated information portal, accessible at any time, from any location. A recent development in cloud computing is the growing popularity of the pay-as-you-go model.

- The metrology equation. The most promising research in production metrology is the development of in-line metrology methods and tools that are combined with strategic measurement planning. The latter is a key-factor in order to reduce costs in the assembly process due to poor quality, which may result savings as high as 40 per cent on the total production cost.

- Adaptive scheduling. “Just in Time” is a manufacturing principle that has been around for many years, but few companies can pride themselves on having realized the concept. A tool that could potentially change all this is the Demand Responsive Planning (DRP) system which provides a fast route to workload control by systemizing the flow of activities.

- Bridging the gap. Most support systems in industry today are based on PLC (Programmable Logic Controller) – a technology that was developed in the 1960s. Now is the time to invest in a series of steps that will introduce responsive and self-optimizing systems that can adapt to changing product ranges and deliveries.

- Total connectivity. Creating the conditions for total connectivity – incorporating customer requirements, design, production and distribution – will be a key challenge over the next few years. To make a modern production system work efficiently, all data related to a product needs to be collected and analysed at every step, and then channelled to the right user.

- The next frontier: additive manufacturing. Minimizing waste in the production cycle makes as much sense for business as it does for the environment. Adopting ecologically-geared processes will become a matter of competitiveness in the years ahead and a wide range of new approaches are now being tested and refined.

Both Sweden and Europe in large are predominantly driven by their industries, and any downturn in this sector influences its welfare society. Manufacturing is a major socioeconomic force and, as such, disregarding its needs would be catastrophic.

– Digitalization has to be tackled in one way or another. We are in complete agreement with KTH that now is the time to re-evaluate current IT systems. Companies that focus on the advantages of modernization stand a far better chance of surviving the storm, but also of building a prosperous future, says Per Håkansson.