Fibria announced that it will build a new nursery at its Tres Lagoas Unit located in the state of Mato Grosso do Sul. The nursery will feature last-generation technology from the Netherlands for automating the entire eucalyptus seedling production process, in an unprecedented initiative in the industry.

According to Fibria, it will be the first pulp company to use robots to plant eucalyptus seedlings. This is the first step of the process, which conventionally is performed manually. Automation helps to prevent losses and to protect the integrity of the seedlings.

The new nursery also adopts concepts such as sustainability and reducing waste and environmental impacts by replacing the old plastic containers in seedling trays with more modern materials made from biodegradable paper, Fibria said.

The new facilities will have approximately 48,000 m2 of greenhouses and have fully automated transportation, handling, selection, irrigation, nutrition and climate-control processes.

In the second step, when seedlings are selected to be moved to an area optimized for their development, the nursery's new machinery equipped with 3D vision will monitor the evolution of the seedlings and improve cultivation efficiency. The new system will generate statistics on the genetic material and development of each plant, which will assure Fibria greater quality control for the seedlings to be planted in the field.

"We will have a state-of-the-art nursery with extremely high precision in terms of systems and environmental control to ensure higher levels of performance in accordance with Fibria's seedling standards. Better seedlings are the foundation of a better forest," explained Aires Galhardo, Fibria's Chief Forestry Officer.

In addition to optimizing operations inside the nursery, the new technology's use also brings improvements for workers. "The new method will provide ergonomic benefits for employees. Another new feature is the control of irrigation and climate via the use of automated panels. It's technology improving the process and quality of life for employees," said Tomás Balistiero, Fibria's Forestry General Manager in Mato Grosso do Sul.

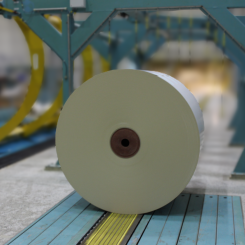

Construction on the new nursery is expected to begin in March 2016, and its startup is slated for March 2017, with annual production capacity of 43 million eucalyptus seedlings. The seedlings will be used for planting and forming the forests that will supply Fibria's Tres Lagoas Unit and the Horizonte 2 Project, which is the company's second pulp production line in the city and is slated for startup in the last quarter of 2017.

Fibria's new nursery will be built through the Dutch consortium Hortikey, which develops large-scale automation projects for companies in the international market. The consortium is formed by leading industry companies, such as Agri-tech Aris, Berg Hortimotive, Bosman Van Zaal and Sistemas de Flier, as well as the Brazilian companies Methodo Ferramentaria, which will provide support on local standards, rules and regulations, and Açopema, which will supply the greenhouses.

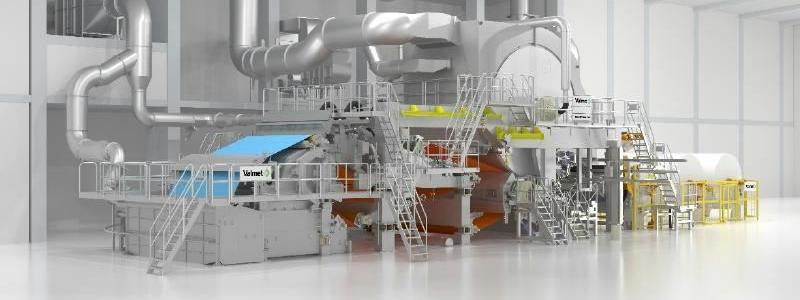

Construction on the Horizonte 2 Project began in 2015 and is advancing on schedule. With an investment of R$8.7 billion (equivalent to around US$2.2 billion), Fibria's expansion project will create 40,000 jobs during construction and 3,000 direct and indirect jobs. The Tres Lagoas Unit will have its annual pulp production capacity expanded by 1.75 million tons. With this expansion, Fibria's Tres Lagoas Unit will have total annual pulp production capacity of 3.05 million tons, making it one of the world's largest pulp producers.