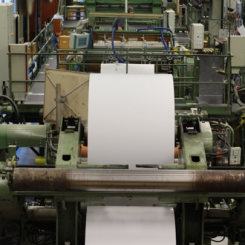

Toscotec has launched TT Defender, a groundbreaking innovation in the tissue market that consists of a special coating for the internal surface of its TT SYD steel Yankee dryer for protection against corrosive steam. TT Defender has been successfully applied on a TT SYD that is operating at Lucart’s Diecimo tissue mill in Italy.

Since steel Yankee dryers have outperformed cast iron Yankees and replaced them as the new technological standard of the tissue industry, more pressure has been put on paper mills to more frequently check steam quality. In order to maintain steam parameters such as pH and conductivity within the correct range, increased monitoring and expertise has become a “best practice”. TT Defender is Toscotec’s pioneering solution: an extremely uniform layer ensuring excellent resistance to highly corrosive conditions. It prevents the risk of chemical corrosion and related problems including mechanical abrasion, erosion, and straw pipes plugging that can lead to an uneven humidity profile.

By virtue of its extremely low thickness, TT Defender does not affect the high drying efficiency of TT SYD. Instead, it increases its O.E.E. (Overall Equipment Efficiency) by greatly reducing the risk of unplanned maintenance stops due to soda straw plugging or internal corrosion issues and reducing time needed for regular internal inspection. This all leads to a greater plant performance.

Jacopo Bibbiani, Toscotec R&D mechanical engineer, says, “We constantly upgrade the design of TT SYD. TT Defender stems from this very logic of continuous improvement: based on the service experience we acquired in more than 20 years on over 200 TT SYD operating around the globe, this innovation is set to make the difference for many paper mills. Customers will benefit from the excellent performance of TT SYD and will be able to enjoy a higher flexibility in controlling the water quality of their steam and condensate system.”