.The packaging test center Brobygrafiska was hit by a total visitor ban due to restrictions following the corona virus. But that did not mean that everything else had to stop. Instead, they went online and let customers test print packaging just like before, but remotely.

The school and test center Brobygrafiska in Sunne, Sweden, is known as a creative packaging, print and design hub. So, it was not surprising that they quickly found an innovative solution to COVID-19 visitor restrictions.

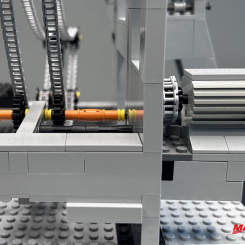

The printing hall is now rigged for testing sessions via video link. By using four cameras, the staff helps customers analyse cardboard materials and printing techniques. And everything can be followed remotely via a computer: from the printing press to the light table and all the way down to microscopic level.

"The customer feedback has been positive. I think this digital solution is here to stay. Now we can reach even more packaging producers around the world", says Per Branzén, Development Manager at Brobygrafiska.

Up to date and ready to go

A digital test day at Brobygrafiska begins with an online meeting to plan the day. The cameras roll throughout the day and customers choose which parts of the process to follow. The secure transmission is handled by a technician who adjusts the cameras according to the customers’ need.

"Since we are a polytechnic, we are always updated on technology and competence. That is a big advantage. The staff is used to quickly adopting new solutions, so there was no problem to go digital. Just as before, we convey knowledge, provide advice, develop and solve challenges. The only difference is that we cannot be in the same room", says Per Branzén.

Corona times are development times

All education at Brobygrafiska is also done remotely. Spring means graduation time and usually this time of the year, the premises are crowded with students doing degree assignment, day and night. But not now. All submissions are digital.

"That is why this is a great time for companies to develop new solutions in our test environment. The equipment is not currently used by students and we are here to make the days as active and value-creating as possible for students, customers and staff", says Per Branzén.

A collection of testbeds for sustainable packing

Brobygrafiska’s testbed is part of the Vinnova-funded project FFLAM, where more than 30 companies and organisations collaborate to develop fossil-free packaging solutions. The initiative is managed by Paper Province and in addition to Brobygrafiska, the test environment includes UMV Coating Systems in Säffle and RISE in Stockholm.

"As a business cluster, we notice that some companies are in a less busy period than normal, as an effect of corona. So, it might be extra useful in these exceptional times to invest more time in innovation and development. That way you can be ready to launch sustainable solutions when the economy recovers again", says Peter Edberg, Project Manager at Paper Province.

Den första onlinekörningen på Brobygrafiska var 16 april och den digitala lösningen är här för att stanna.

The first online session at Brobygrafiska was in April and the digital solution is here to stay.

More information and contact