Valmet will supply two containerboard production lines and related automation systems for Nine Dragons Industries Co., Ltd. in China. The new production lines (PM 39 in Quanzhou and PM 40 in Chongqing) are planned to produce high-quality testliner and fluting grades out of 100 percent recycled raw materials. The start-ups of the machines are scheduled for 2018.

The order was included in Valmet's fourth quarter of 2016 orders received. The value of the order will not be disclosed. The value of an order of this type and scale is typically valued around EUR 110-130 million.

"The order is a continuation of the long and good cooperation between Nine Dragons and Valmet. We have done business together for many years. In a project of this magnitude, the customer needs to have a reliable partner to ensure fast start-up and good capabilities for continuous services and production support", says Jari Vähäpesola, President of Paper Business Line, Valmet.

"The modern industrial design of the board machines proved to be important decision making criteria as well. The delivery will include led lighting and video screens located at the both ends of the machine. In addition to increasing safety and usability, they have a positive effect on the customer's brand. The board machines are also very energy and resource efficient and suitable for high-speed production", comments Senior Sales Manager Pekka Turtinen from Valmet.

Led lighting and video screens increase safety and usability and have a positive effect on the customer's brand

Valmet's delivery for the both board machines will include pulpers for stock preparation, two OptiFlo Fourdrinier headboxes to ensure higher productivity, OptiFormer Multi forming section, a center-roll based OptiPress press section, a dryer section with OptiAir high humidity hood combining systems for ventilation, runnability and heat recovery, OptiSizer Combi, a sizer with film and pond application, coating air dryers, OptiCalender Hard nip calender, OptiReel Center driven linear reel and OptiWin Drum two-drum base winder. The delivery includes also process ventilation equipment for the board machine and Valmet DNA machine control system.

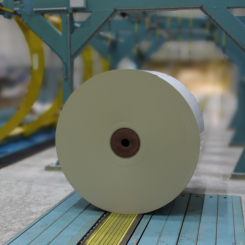

With OptiReel center driven linear reel, the parent reel is moved and built up on solid rails. This new technology increases productivity and improves safety and usability. OptiWin Drum two-drum base winder has a high capacity to meet the production needs and it is also easy to operate. The winder is equipped with Dual Unwind enabling the parent roll change in only one minute. PM 39 and PM 40 will produce testliner and fluting grades with a basis weight range of 75 - 140 g/m2.