Huatai Group, a leading player in China's pulp and paper sector, has unveiled plans for a transformative 16-billion-yuan ($2.3 billion USD) integrated forest-pulp-paper project in Yulin, Guangxi province. This state-of-the-art facility aims to produce 400,000 tons of dissolving pulp, 600,000 tons of chemical wood pulp, and 900,000 tons of eco-friendly industrial paper each year, supported by a vast 1.5-million-mu (approximately 100,000-hectare) raw material forest base. The project exemplifies the industry's shift toward vertical integration, connecting forestry, pulp production, and paper manufacturing to mitigate raw material price volatility and enhance supply chain resilience.

The initiative comes amid China's aggressive capacity expansion in the pulp and paper sector, driven by rising domestic demand for packaging, hygiene products, and industrial papers. With e-commerce booming and urbanization accelerating, companies like Huatai are positioning themselves to capitalize on these trends. The project's location in Guangxi leverages access to low-cost timber resources from Southeast Asia, providing a competitive edge in production costs. This forest-pulp-paper model not only secures raw material supply but also aligns with national policies promoting a circular economy, including extended producer responsibility (EPR) and subsidies for recycled content.

Industry analysts note that such integrations are becoming standard as profit margins shrink and pulp prices fluctuate. By 2024, China's top five pulp producers already controlled 45% of the market, signaling increasing concentration. Huatai's project, set to commence operations from late 2025 through 2026, will further amplify China's dominance in global pulp trade flows. Coastal regions like Shandong and Guangxi are hotspots for these developments, with Sun Paper's Beihai base also advancing. Between January and August 2025, China's machine-made paper and paperboard output reached 106.659 million tons, up 2.7% year-on-year, underscoring the sector's momentum.

From a business perspective, this investment addresses key challenges in the Asian pulp and paper market. E-commerce-driven packaging demand, coupled with manufacturing expansion, has spurred over $34 billion in tracked capital projects across Asia, with China leading at over $23 billion. Indonesia and India follow with $3 billion and $1 billion respectively. Huatai's facility will contribute to grassroot developments (44% of investments) and expansions (48%), focusing on high-value products like dissolving pulp used in textiles and eco-friendly papers for industrial applications.

Sustainability is integral to the project. The eco-friendly industrial paper output emphasizes recyclable and low-emission production processes, responding to regulatory pressures for green procurement. Guangxi's forest base will promote sustainable forestry practices, reducing reliance on imports and supporting China's carbon neutrality goals. This aligns with broader Asian trends, where governments incentivize bio-based materials and waste management innovations.

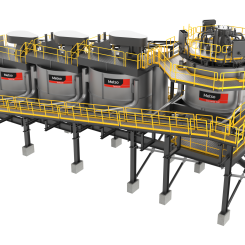

For stakeholders in papermaking, chemical pulping, and environment management, Huatai's project sets a benchmark. It enhances operational efficiency through process automation and controls, potentially incorporating advanced pumps, mixers, and water treatment systems. Partnerships with technology vendors for debarking, wood preparation, and chemical recovery are anticipated, boosting categories like industrial equipment and power systems.

The global implications are significant. China's capacity surge is reshaping pulp markets, influencing prices and exports—China exported $29.8 billion in paper articles in 2024. Competitors in Indonesia and Vietnam must innovate to counter this. For decision-makers, this signals opportunities in project management, consultancy, and supply chain logistics as Asia's sector invests heavily in growth.

Huatai's bold move reinforces China's role as the epicenter of Asian pulp and paper innovation, promising long-term stability amid economic hurdles. As production ramps up, it will drive demand for ancillary services in safety, materials handling, and steel components, fostering a robust ecosystem for B2B players across the region.