Valmet will deliver a new evaporation line to Altri Biotek mill in Portugal. This delivery is part of Altri’s EUR 75 million project to convert the Biotek mill to produce dissolving pulp for textile industry. The new evaporation line significantly improves the mill’s energy and water efficiency, meeting the needs of Altri’s mill expansion.

“Changing the production from kraft pulp to dissolving pulp will enable the Biotek mill to take a strategic step into the renewable textile fiber markets. We at Valmet are proud to deliver lifecycle value to our customers to meet the needs of tomorrow, both by upgrading existing mills and meeting the global circularity demands. Our extensive expertise in industrial processes combined with our innovative technology enables us to deliver these energy and water efficient solutions for the mill conversion and we look forward to a successful, efficient collaboration with the Altri team,” says Sami Riekkola, Executive Vice President, Pulp, Energy and Circularity, Valmet.

“The evaporation line will contain the latest technology which provides significant steam savings with the 7-effect design and clean condensates to be reused in the mill. Additionally, the combination of Valmet Tube and Tubel evaporators provide long lifetime and high availability,” says Karin Bengtsson, Product Sales Manager at Valmet.

The order is included in Valmet’s orders received of the third quarter of 2025. The value of an order of this size and delivery scope is typically around EUR 25–30 million. The new evaporation line is planned to start up during the third quarter of 2027.

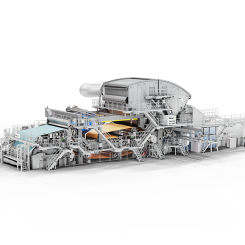

Details about Valmet's delivery

Valmet’s delivery includes a new 7-effect Valmet Evaporation Line with a design capacity of 350 tons of evaporated water per hour, producing heavy liquor of 75% dry solids. The delivery covers engineering, procurement and installation of the evaporation system.

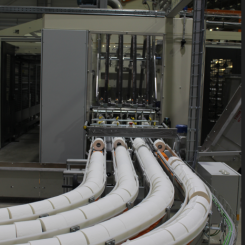

The new evaporation line includes Tube and Tubel Evaporators and that together secure long lifetime, high availability and excellent condensate segregation. The new line is equipped with Valmet Condensate Handling to enable the production of clean-quality condensate which reduces the mill’s freshwater usage.