With the adoption of the Packaging and Packaging Waste Regulation (PPWR), retailers and brand owners are under increasing pressure to reduce their environmental footprint. The regulation sets ambitious targets for packaging waste reduction, recyclability and responsible use of resources. Paper carrier bags meet the highest standards.

They are made from renewable raw materials sourced from sustainable forest management and are reusable and recyclable. But that’s not all: the kraft paper and paper carrier bag manufacturers are constantly working to conserve resources, minimise environmental impact and increase product quality at all stages of the production process – and they have been doing so long before the PPWR came into force.

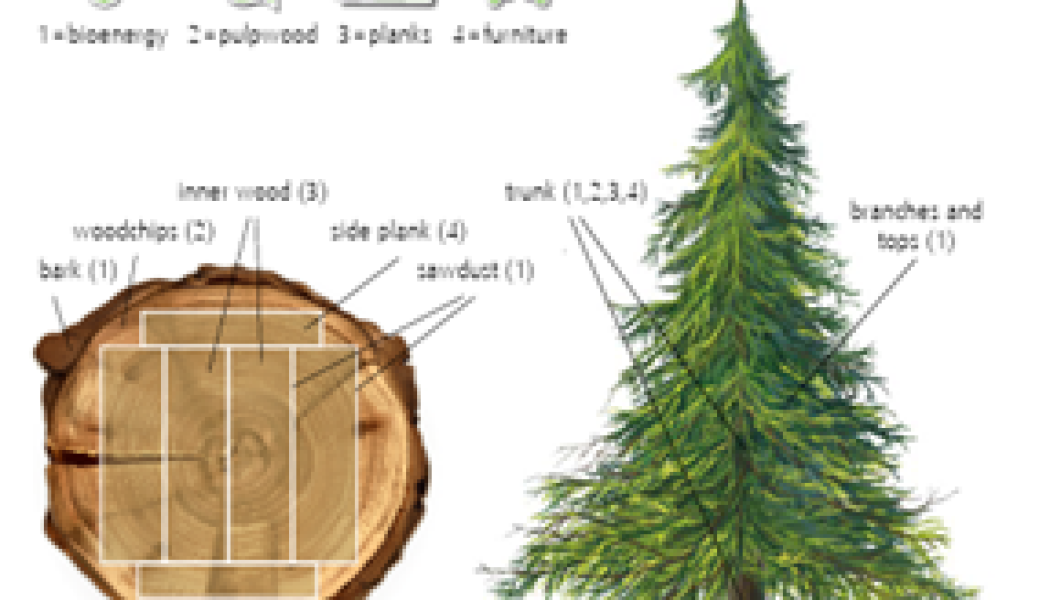

“Saving resources has a long tradition in our industry,” says Elin Gordon, Secretary General of CEPI Eurokraft. “The concept of sustainability was introduced in the early 18th century in connection with the responsible use of wood as a resource. And this principle still defines how we operate today.” The primary raw material for kraft paper is wood fibre, mostly sourced from sustainably managed European forests. In these forests, trees are selectively harvested, primarily removing dead, weak or misshapen ones to support healthy growth. This practice supports the objectives of the EU Deforestation Regulation (EUDR). FSC® certifications also ensure the traceability of the raw materials and confirm that they originate from responsibly managed, deforestation-free sources. Adding to that, the kraft paper industry relies on process waste from the timber industry such as wood chips and thinning wood – this way, no part of the tree is wasted1. ”This no-waste principle is continued throughout the production of kraft paper and paper carrier bags,” explains Gordon. “Wherever possible, materials are utilised and recycled.” One example is that internally generated biofuels, such as black liquor, are used in the mills’ energy mix.

Energy-efficient kraft paper production

Kraft paper production is highly energy-efficient. A large proportion of renewable energy sources is being used, while the reliance on fossil fuels is decreasing. According to a study by RISE2, in 2021, biofuels accounted for 92% of all fuels consumed for kraft paper production, with 78% being generated in the mills during the production process. Additionally, the mills produced 59% of their own electricity requirements. Of the purchased grid electricity consumed by the mills in 2021, 29% was identified as “green” electricity.

Recycling water in paper production

In addition to energy, water is used efficiently and responsibly in the papermaking process. Most pulp and paper mills are strategically located near abundant water sources. In Europe, the majority draw primarily from surface water – rivers and lakes account for 87% of their intake. Groundwater provides another 12%, while only 1% comes from public water supplies. Since the 1990s, the industry has reduced the average water intake per tonne of paper by approximately 40%. Modern paper mills treat and reuse process water multiple times before returning around 90% to its source in a clean state. The remaining 10% either evaporates, remains in the product or is retained in solid waste3.

Reusing production waste

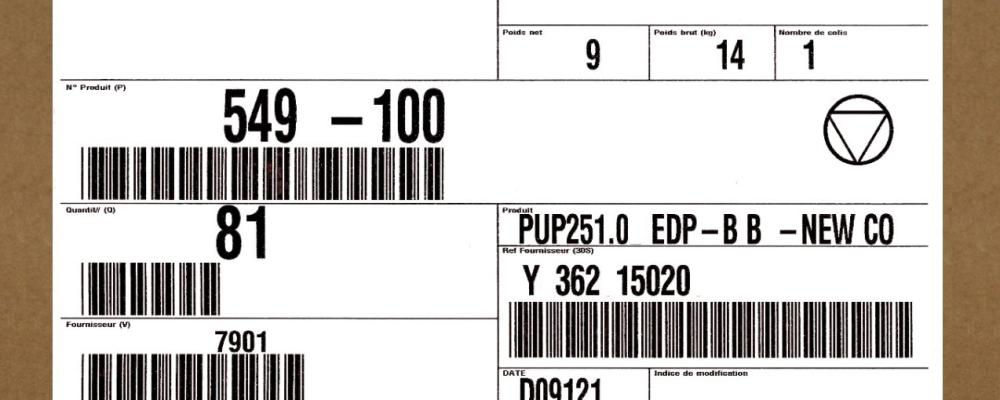

Residuals from kraft paper production, such as pulp residues, are fed back into the production cycle. When it comes to conversion, the paper carrier bag converters order paper in the exact quantity and size required for each order. Any waste generated during machine set-up, as well as production residues, are carefully sorted by type and turned to recycling. Remaining inks and adhesives are stored and reused for future orders. “This contributes to a closed-loop manufacturing process that minimises landfill waste and supports material efficiency,” states Gordon.

Smart design: less is more

Paper carrier bags are designed to use only the amount of material needed to meet performance requirements. Their material efficiency has improved in the last two decades, with the strength of kraft paper having been optimised by 45%. The durability of high-quality paper carrier bags allows them to carry heavy loads with minimal material use. This aligns with the PPWR’s emphasis on reducing unnecessary packaging.

Reusability and recyclability

Thanks to their strength, high-quality paper carrier bags can be reused several times. Reusing a bag as long as possible conserves natural resources that would otherwise be utilised in the production of a new bag. And when it is no longer suitable for reuse, paper carrier bags can easily be recycled through local waste streams. According to a study, paper based packaging can be recycled more than 25 times. The fibres can be repurposed into new paper products – from newspapers to corrugated packaging. “In our industry, sustainability is not a trend, but a tradition that evolves through innovation,” concludes Gordon. “With paper carrier bags, we offer a future-proof packaging solution that comes from nature and gives back to nature – the perfect choice for retailers and brand owners who want to lead the shift to a circular bioeconomy.”

“Simple choice, big impact”

The Paper Bag platform will celebrate the 8th European Paper Bag Day on 18 October 2025 under the theme “Simple choice, big impact”. Activities across Europe will highlight how choosing paper carrier bags as a sustainable packaging option can make a significant difference for the environment. Retailers, brand owners and consumers are invited to join the celebrations and share their activities on Facebook, Instagram and LinkedIn using the hashtag #EuropeanPaperBagDay.