DS Smith announces that they recently extend their footprint into both Italy and Poland. The new energy-efficient sites will meet the rising demand for sustainable packaging and minimise carbon emissions.

With a combined investment of £100m, the new state-of-the-art packaging facilities were formally launch on 13th and 15th of September in Castelfranco Emilia, Italy and Belchatow, Poland.

The Italian and Polish sites will focus not just on recyclable fibre-based packaging, but on market requirements for solutions to replace plastics. The facilities will generate more than 250 new roles across both communities.

“As well as increasing capacity, the investment reflects our commitment to grow sustainably while minimising emissions in our operations and supply chain. The plan is one of the most ambitious decarbonisation plans in Europe and is based on a science-based target to reduce emissions by 46% by 2030 and to achieve Net Zero by 2050”, DS Smith writes in a press statement.

"The good growth we have seen in Italy over the years is continuing and we are seeing a lot of customer interest in our sustainable packaging innovations. With state-of-the-art technology at Castelfranco Emilia and Belchatow and our long established, fully fibre-based approach, we’re very well placed to meet demand in both markets”, says Miles Roberts, Group Chief Executive at DS Smith.

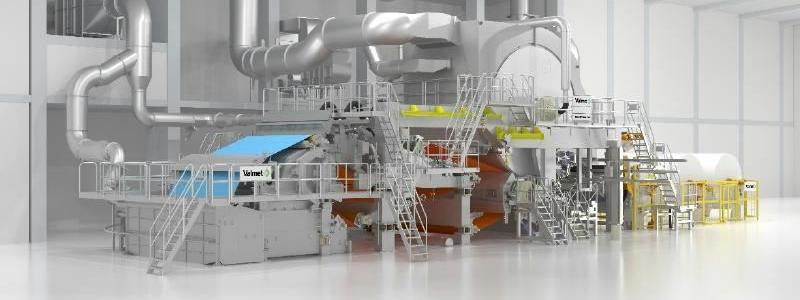

Supporting sustainability with innovative technologies

Technologies at the new sites will be leading-edge. At Castelfranco Emilia, automated vertical warehousing will communicate automatically with machines on the factory floor to maximise productivity, as well as decreasing the physical footprint to increase safety and efficiency. At Belchatow, a range of technologies including Augmented Reality will help customers visualise and co-create new sustainable innovations with DS Smith experts, supported by analysis of market trends and shopper behaviours.

In line with our sustainability strategy, the factories will be as energy efficient as possible. For example, at Castelfranco Emilia, the site will be air conditioned by a geothermal system which takes water from a 90m deep underground well, keeping the site warm in winter and cool in summer.