Alan Werker and Simon Bengtsson are experts in environmentally smart and innovative technologies. Above all they know how to convert waste and wastewater into renewed resources – such as biobased and biodegradable plastics. New building blocks that are essential for a circular and sustainable society.

Swedish researchers Alan Werker and Simon Bengtsson are driven by passion in commitment to the environment.

One of the technologies in their toolbox results in the biopolymer PHA, a natural thermoplastic like building block that can be used as an ingredient for bioplastics.

Bioplastics have many advantages over plastic made from fossil components. They are biodegradable and can be biobased if they are produced as a by-product of existing, and also essential, organic waste and water treatment processes.

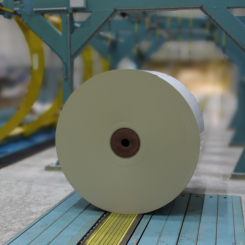

Alan and Simon have extensive knowledge and experience of methods for producing PHA from municipal sludges as well as from residuals from pulp and paper mills.

“We have worked for a long time on this and developed technology all the way from basic science to proven application – and we have seen that it works”, says Simon Bengtsson.

Bioplastic production can be part of the solution to the global environmental challenges, but Simon and Alan would prefer to see PHA as a valued raw material with own unique properties, not simply as a replacement for modern day plastics.

“It is a product that is renewable, and this is necessary in the challenges that we face in the world. But we think it is important to point out that it is a polymer with its own potential in advanced applications. For example, it can be used in specialized coatings or composites linked to products from the paper industry”, says Alan Werker.

This is also something that is currently being evaluated in the Vinnova sponsored project FFLAM - Fossil Free Laminates. The intention is to nurture developments of fossil-free laminates that can replace or reduce needs for fossil-based packaging materials.

Collaboration beyond borders

Alan and Simon started Promiko AB, four years ago. It is located in Lomma in southern Sweden but collaborates with companies and research teams throughout the country, as well as far beyond the Swedish borders.

They work with troubleshooting, optimisation, and developments with innovative technologies and bioprocess implementations for the environmental sector including water quality management and water distribution, in addition to their long-standing passion with biopolymers.

Environmental commitment makes for meaningful work

An environmental commitment gives them an impetus to do the work they do. Waste without conversion and circularity is a problem, they argue.

“In the past, the challenge was treating effluents to reduce the impact on the environment and protect public health. Now society increasingly realises that it is not just about avoiding impacts from waste, but to also recapture resources that can be converted and re-utilized, again and again”, says Alan Werker.

“We support a development where society finds that smart waste conversion can be of greater utility and a more effective management strategy. Promoting change with technology and behaviours in practice that can nurture sustainable living gives meaning.”

Promiko is a member of Paper Province, a world-leading business cluster within the forest bioeconomy. A natural network to be part of because their cutting-edge expertise is applicable to many fields and opens doors for new partnerships and business ideas in the bioeconomy – all over the world.