There is a new revolutionizing product on its way into the construction industry; lightweight studs made of wood-based pulp. The new stud improves the working environment for carpenters as well as contributes to a more sustainable construction process. “One stud made from metal has the same carbon dioxide emissions as fourteen made of paper,” says Tobias Söderbom Olsson at Wood Tube.

The Swedish innovators Kurt Härdig and Patrik Kämpe wanted to reduce the construction industry’s negative impact on the environment. They had an idea of using paper to manufacture studs and after extensive testing that showed good strength and potential, the company Wood Tube was founded. Later Tobias Söderbom Olsson joined the innovative gang.

Now, Wood Tube is a new member of the world leading bioeconomy cluster Paper Province and is very close to launching its patented product on the market.

Wood Tube’s studs can be used in many ways but are especially suited for building interior walls and furniture.

“The client will get an environmentally friendly construction, the construction company saves money and the carpenter gets a better working environment,” says Tobias Söderbom Olsson and continues:

“The studs are cost effective, climate smart, easy to cut and work with. The carpenters avoid heavy lifting, sawdust in the workplace and cutting injuries that are otherwise common when working with metal studs.”

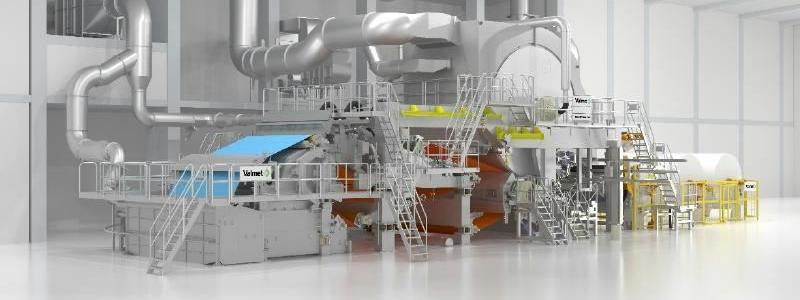

Currently the studs are manufactured in Germany, using raw material from Sweden. But Wood Tube are about to establish production somewhere in Sweden, in the region Värmland that is rich in both forests and pulp and paper mills.

“We ended up in Germany because the machine manufacturer is based there. But we want to move production closer to home as soon as possible.”

Making a positive contribution to the climate is important for Wood Tube. A life-cycle analysis made with help from Karlstad University showed that their stud emits fourteen times less carbon dioxide than a similar one made of sheet metal.

“This is a product that is used in large volumes so we can make a real difference. A lot of carbon dioxide is emitted when producing steel, as opposed to our product. And when it comes to replacing wood, the advantage with our studs is that less material is needed. Wood is a great material, but you might have to think about where to use it best, as in load-bearing structures or where you can see and experience it – instead of hiding it inside a wall,” says Tobias Söderbom Olsson.