As the only European manufacturer of viscose short cut fibres for paper applications, Kelheim Fibres GmbH has become firmly established within the paper industry.

Newly developed speciality fibres perfectly adapted to the needs of paper manufacturers add to Kelheim's already broad range of products.

Bellini, for example, is an ultra-flat fibre which excels in particular as a result of its extremely high self-bonding properties. Even an addition of only 5% of Bellini fibres in a paper ensures a significantly higher tensile strength and resilience in the end product. Tests carried out by the Graz University of Technology* have specifically shown more than twice the number of double folds in papers containing Bellini compared to the control paper. In addition the results for elongation, tear length and tear resistance could each be improved by more than 20%.

Bellini therefore is an ideal partner for all challenging speciality paper end uses - but also an interesting choice in view of the worldwide growing demand for paper and the subsequent necessity to recycle papers: by adding Bellini fibres a paper's properties can be optimised so as to increase the proportion of recovered paper used, yet at the same time maintain the quality of the end product - an ecologically and economically attractive aspect.

Due to its unique cross section, Kelheim's Danufil® fibre is ideally suited to control the porosity of a paper. Depending on the pulp used, the addition of 10% Danufil® fibres achieves a decrease of a paper's density by 10% - but at the same time the air permeability (porosity) according to Bendtsen rises by almost 90%.

Danufil® fibres are therefore used for all products which request a fast exchange or passage of air and liquids; typical end uses are tea bags, cigarette papers, filter papers or papers for vacuum cleaner bags.

Along with Bellini and Danufil® Kelheim Fibres presents at this year's Zellcheming a range of speciality fibres which have been particularly developed for the paper industry.

At the same time, the fibre specialists focus has been first and foremost on tailor-made new developments generated in close cooperation with the customer.

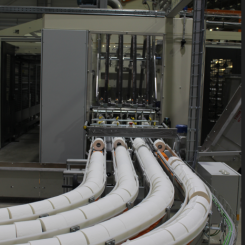

For this purpose Kelheim Fibres has extended its in-house Paper Competence Centre. With the new pilot plant with inclined wire technology all kinds of fibres, pulp and - if required - different additives can be processed to papers with surface weights from 20-200g/m2. The new inline dryer enables the production of larger samples.

Kelheim Fibres can therefore quickly prove the results of their fundamental research in cooperation with the Institute for Paper-, Pulp- and Fibre Technology of the Graz University of Technology in innovative paper products. The new Paper Competence Centre is also available for Kelheim's customers' own trial work.

Test runs on big production plants are expensive but with the new pilot plant the customers can make the first steps in developing innovative papers - and engineer these new products in close cooperation with Kelheim's R&D fibre experts.