Bel Papyrus Ltd, member of the Lebanese Boulos Group Of Companies, situated in Lagos Nigeria, have concluded the purchase of a state of the art tissue production line with an average production of 65 tpd from Toscotec. The new line will consolidate the company's leading position in West African tissue market raising total production capacity above one hundred and twenty tons per day. The new line, integrates a new DIP plant also supplied by Toscotec, is expected to come on stream at the end of this year.

With the new PM3 line, installed within the Ogba compound, the company will become one of the largest and most advanced tissue producer in Africa.

The total cost of the project is financed by a combination of Capital injection of 15,000,000 US Dollars from the shareholders, and a 20,000,000 US Dollar term loan secured by Citibank. The loan to the company is guaranteed by the Overseas Private investment Corporation (OPIC) from the United States Government.

The Boulos group was established in 1936 by George Boulos and his sons Antoine and Gabriel and by 1980 established a large capacity manufacturing plant for Suzuki motorcycles thus becoming one of the country's leading industrial groups.

In 1986, the group established Bel Papyrus Limited and bought their first paper recycling and tissue paper production from Toscotec. In 2004 Bel Papyrus bought a Toscotec Modulo line and increased capacity to fifty tons per day.At the same time the group established a tissue paper converting factory, Bel Impex Limited, to produce a large array of tissue paper products utilizing state of the art European machinery.

With a tissue converting capacity of 22.000 tons per year coming from Toscotec machines, actually BIL produces and distributes several products and brands of tissue papers. The range includes toilet, facial, pocket handkerchiefs, table napkins and kitchen towels.

On line with its diversification policy, BIL has launched its 3rd generation Baby Diaper "Rose Tenders", a product of international standard, and is planning to start production of Aluminium Foil, Cling Film, Wet wipes and Sanitary Napkins in the very near future.

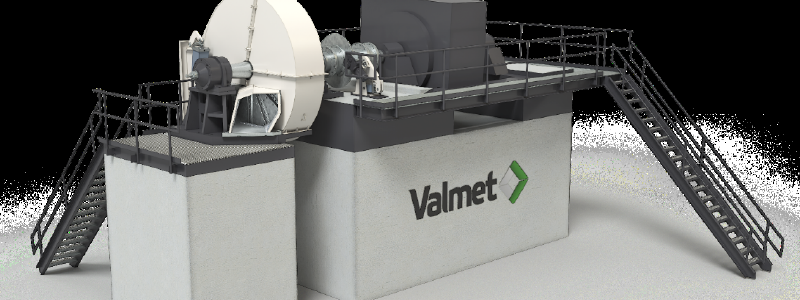

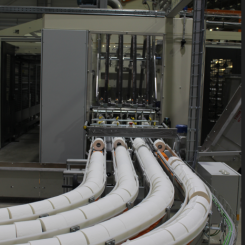

The new Toscotec's line includes AHEAD 1.5S crescent former tissue machine with single-layer headbox, single press configuration and a Steel Yankee Dryer (TT SYD 12FT), machine auxiliaries, stock preparation plant for virgin pulp and for recycled paper including deinking cells, 2-loop washer system and a hot dispersion system and the electrification starting from medium voltage cabinets and control system.

The supply contract also includes: a steam generator, air compressors, a three unwind stands tissue slitter rewinder TT WIND-P with calendering station and a jumbo reel wrapping machine.

The machine design speed is 1800 mpm with a net web width of 2850 mm. The project will be managed by Toscotec on an EPC (Engineering and Procurement) basis.

The long term and successful cooperation between the two companies, Toscotec's technology and its vocation to provide "state of the art" equipment and realize complex "turn key" projects worldwide, has been the decisional factor for Bel Papyrus Ltd to choose once again the Lucca based company for this challenging project