NCR Corporation has integrated two-sided thermal label printing technology at its consumables product warehouses in Ontario, Tennessee and Arizona, streamlining its shipping processes and reducing associated costs by 30 percent.

By using NCR’s 2STTM two-sided printing technology for label printing, the company is able to print a packing slip on the back side of shipping labels, changing the old process of printing separate documents and eliminating related materials such as printer toner and a plastic document pouch. The reduction of these consumables eliminates 65,360 lbs. of material from being produced, shipped and added to landfills annually -- a significant positive environmental impact.

"NCR is the pioneer in two-sided thermal printing. It was only natural for us to prove the cost and environmental benefits of 2ST by implementing it within our own enterprise," said Dan Bogan, senior vice president and general manager of NCR Consumables Solutions, a leading provider of printer consumables. "Shipping costs are significant for most every company. We believe that our 2ST label printing solution can have a major impact in helping businesses reduce their related operating costs while realizing meaningful environmental advantages."

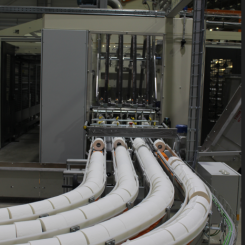

NCR began implementing 2ST label printing into its warehouses in Mississauga, Ontario, Morristown, Tenn., and Tempe, Ariz., in November 2010. The company was able to eliminate the cost of buying, shipping and storing laser-generated packing slips, toner to print the packing slip and plastic pouches. Time savings realized by making the process more efficient allow NCR employees to focus on other value-added activities in the warehouse. A SATO GY412 2-sided label printer is used in this solution, along with ConnectShip, a leading shipping application.