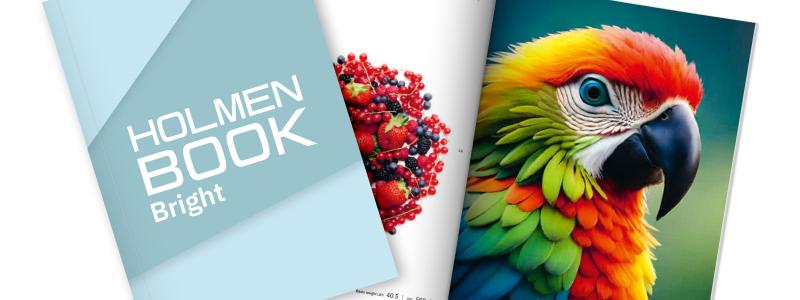

Mondi Consumer Bags & Films has developed a new process for direct rotogravure print on a´barrier laminate made of Paper/PE/Aluminium/PE. The result is an evolution in direct, highquality rotogravure print offering reduced lead times and higher flexibility in designs.

Convenience, product safety and attractive design are the three top priorities for packaging in the consumer goods industry and play an even bigger role in the dehydrated food segment, which requires high barrier properties and therefore costly production processes. Mondi accepted this challenge and came up with an in-house solution that offers customers an efficient and flexible technology for premium print quality on high-barrier laminates.

"To meet the demands of high-quality prints and product safety, rotogravure printing technology and multi-layer barrier laminates are a necessity. The downside was: both result in high printing volumes and low flexibility in design changes", Christian Kolarik, Managing Director, Mondi Consumer Bags & Films, explains. "We are happy to offer our customers an innovative solution, which enables them to be more flexible whilst being cost-efficient at the same time", he proudly states and concludes, "many companies have tried to come up with a solution, but they never quite managed. Thanks to our experienced team of application engineers and development managers, Mondi is the first company to provide its customers with an efficient and top-quality solution."