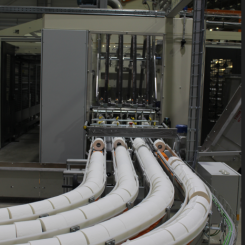

TRM has invested in a new high-tech corrugator. The BHS 2.8m corrugator, which comes with a neater slicing function and the most up-to-date slitter/scorer in the UK, has just been installed at the company’s Burscough plant in the second phase of a £12m investment plan. The German-built beast – which resembles a sleek intercity train, and is capable of running at 250m a minute – took the TRM team just 12 days to install and utilises the very latest pressure sensor technology for optimum board manufacture and flute profile. Although the installation necessitated a temporary shut down in part of the factory, normal service was resumed in record-breaking time, resulting in the least possible disruption to TRM and its customers. Steve Edwards had nothing but praise and respect for his team of engineers who helped to make this possible.

"I can’t praise the guys involved highly enough. This was a big project and the smooth-running of the operation made all the difference," he said. "The new corrugator allows for a much neater edge on the sides of the boxes and thus better presentation of the final packaging. Our new machine is already making a huge difference to TRM’s already impressive output."

As the biggest employer in Burscough, TRM has already invested up to £7m in the business and the growth plans are expected to increase turnover by £30m to £40m over the next three years.