The high-performance rotary cutting die called marbspeed-r is the latest development of the Heilbronner, Germany, diemaker Karl Marbach GmbH & Co. KG. This innovative tooling technology for corrugated board is mainly characterized by its extremely high performance.

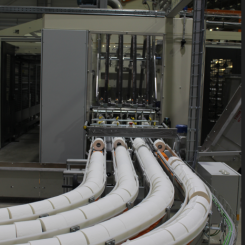

The reason for this is that marbaspeed-r is equipped with brand-new, special high-tech rubbering. This means, elastomers are used instead of natural rubber material. These elastomers have the advantage that they are highly resistant and durable. And their production is eco-friendly without propellant.

Rubber material is not all. Also the correct positioning of the rubber in the die is very important for the effectiveness of this brand-new rotary cutting die. This is based on a perfectly developed system of rubber positioning and mounting which leads to optimum results. Due to more than 40 years of experience in producing rotary cutting dies Marbach provides the required know-how.

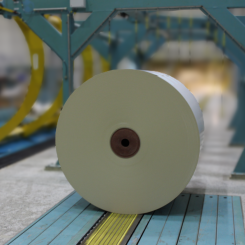

Mr. Christian Wala, Plant Manager at Wellpappe Forchheim GmbH & Co. KG (Palm Group) is convinced of this innovation: "We have recently ordered a rotary marbaspeed-r die for a flat-bed job with which we are dealing once a week. Job details are: yoghurt crate, E wave, many waste parts. The result convinced us: marbaspeed-r is opening up a new production method because we are now also able to choose for rotary processing when dealing with this job. This was not possible with a standard rotary die. Besides, we achieve a considerable increase in productivity – in case of the above-mentioned job we experienced an increase of approx. 35% – when using this new production method. And, with marbaspeed-r, we benefit from complete waste disposal. Thank you Marbach for this brand-new solution to increase productivity."