To meet the requirements for very small batches from most of their customers, Goldprint invests in the fully automated Gallop production line for folding cartons supplied by Xerox and Stora Enso.

Located on the ring around Brussels, Goldprint employees 90 highly skilled people on state of the art equipment and has a turnover of 12 million €. The factory is dedicated to the production of printed packaging mainly for pharmaceutical brand owners and contract packers.

"In pharmaceuticals packaging, the batches get smaller and smaller as medication gets more sophisticated and individual. Also variable coding of packages and more efficient anti-counterfeiting solutions are required. All this means that there is a growing need to make different packaging, and the Gallop line is an effective solution for that," says director Luc Meeùs from Goldprint. "With the Gallop we can also expand our service to new segments such as luxury food, chocolate and business gift packaging."

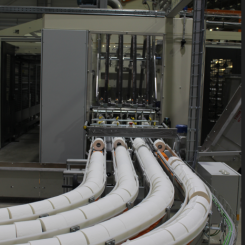

The production line, Stora Enso Gallop Powered by Xerox, combines a Xerox iGen 4 digital production press with a coating unit for UV or waterbased varnish, a buffer-stacker to check the job integrity and a die cutting machine capable to emboss Braille and hot foil stamps. "Stora Enso has made a brilliant job in the integration of the machines into one, inline solution. The digital work process, inline varnishing and the job flow throughout the production line are major improvements for cost-efficiency and delivery speed," Mr Meeùs says.