Not only that – this single press line at Dutch print enterprise Vis Offset in Alphen aan de Rijn has taken the place of two others. “It has increased our flexibility enormously,” says founder Arie Vis. Even though the print media are experiencing a period of wrenching change, Vis Offset management is confident that offset printing has a promising future.

All over the world the graphic arts industry is in the throes of a radical transformation, and the Netherlands is no exception. According to sta-tistics released by the Grafische Bedrijfsfondsen (GBF, the agency which administers pension schemes for the Dutch graphics/media in-dustry), at the end of 2008 the sector had a total of 40,555 registered employees covered by collective wage agreements. On 31 August last year there were 3,687 fewer – a 9.1 per cent decline in just eight months. This means that at present there are still 36,868 people employed by trade printers, screen printers, newspaper publishers and printers and the outdoor advertising industry.

This year employment in this sector is expected to be approximately 20 per cent below the 2008 level. However, a closer look reveals something else behind these figures: while employment is dwindling, productivity continues to climb rapidly.

In August 2009 Mijdrecht-based Wifac, KBA’s sheet fed and commercial web press agent in the Netherlands, installed the first Rapida 75 perfector press in the town. Says Arjan Vis: “We signed the contract with Wifac in November 2008, when the crisis had already broken. If we had to make a decision today it would be no different.” At that time Vis Offset employed twelve staff, but this has since been reduced to ten.

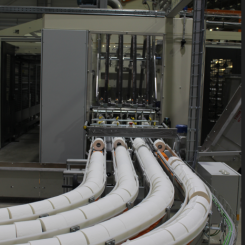

Daniel Vis explains: “A press operator and a print finisher both reached retirement age. We had been printing on a mono press that was al-most twenty years old and on a two-colour press that had served us well for ten years or more. When we came to take a closer look at our order structure, we found that a large proportion entailed two passes, for recto and verso production. Armed with this information we set to work and came to the conclusion that a four-colour press with a per-fecting capability would be the best choice. In the end we opted for the Rapida 75, largely because what struck us particularly about this press is that it can perfect at maximum speed. Another point in its favour is that job changeovers are remarkably short because the impression cylinders and blankets can be washed simultaneously.”

Vis Offset generally runs just a day shift, and management would like to keep it that way. Says Arjan Vis: “The Rapida prints up to 15,000 sheets per hour. But even more important than its maximum speed is the time required to prepare the next job, and the speed with which it runs up to colour. This is where we save both time and waste. One of our customers has his letterheads printed with four PMS colours, which means the press must be cleaned as thoroughly yet as rapidly as possible prior to impression. This is one of the Rapida’s main strengths, alongside extensive automation.”