With Voith Paper's MultiFlex V3 on PM 8 at Saica 2 in El Burgo de Ebro, Spain, the machine efficiency increased significantly. The felt lifetime is now six weeks compared to a previous life of four weeks. Due to higher life time, the shut downs could be reduced which increased the output. "From now on, we will be able to run with all three press felts six weeks. Before we had to change this felt every four weeks", stated Saica 2 Production Manager Carlos Aguirre.

The Saica PM 8 has a trim width of 7.4 m and produces 125-220 g/m² corrugated medium and liner board.

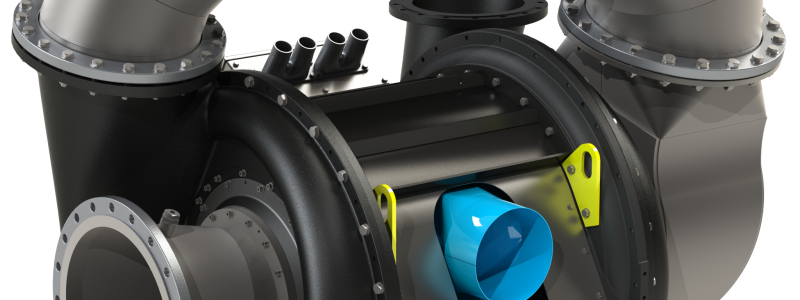

The success of MultiFlex V3 is based on Voith Paper's specialty for the challenges in the press section, the well-proven Vector technology. This comprises a tri-axial non-woven base fabric structure that provides elasticity in all three spatial directions for excellent compaction resistance and self-cleaning properties. It also has high active void volume for controlled dewatering and handling large amounts of water. Even pressure distribution leads to more uniform drying whilst the multi-axial structure provides low flow resistance and maintained permeability.