With the start-up of the new film press at the Niklasdorf mill in Austria recently, Brigl & Bergmeister has completed the 3-phase investment programme launched in 2013, ensuring both mills' future competitiveness.

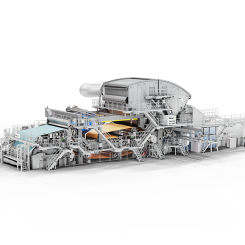

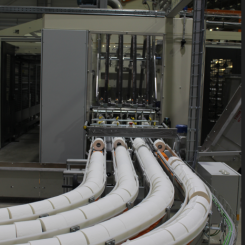

The centrepiece of the rebuild was the investment in a SpeedSizer AT, CB-Turn and a qDryPro supplied by Voith. Lang Hafner was responsible for the redesign of the steam and condensate system, the modification of the heat recovery system, as well as providing a new hood for the paper machine. The complete starch and coating supply system, as well as the modifications to the coating kitchen, were implemented by GAW.

Thanks to the investments made in the paper machine's headbox, wire and QCS (Quality Control System) on the paper machine and the coating machine in Spring 2014, the traditional range of one-side coated papers can now be produced with an even more selective and consistent surface quality. These investments allow Brigl & Bergmeister to offer a complete range of siliconizing base papers (called CCK – Clay Coated Kraft) under the brand name “NiklaSilico” within the sector of “Graphic Arts Applications”. With the new headbox, the maximum achievable grammage has been significantly increased to 137 g/m².

A third embossing calender, also purchased in 2015, ensures additional capacities for embossed papers, which can now also be provided with customised embossing patterns, as are required by clients.

These investments also reflect B&B's motto “Think & Act Green”. Both the Niklasdorf and the Vevče mills already show industry-leading measures in terms of environmental protection. Thanks to the investments made, further energy savings will be achieved in the future by reducing the required steam and electricity consumption.