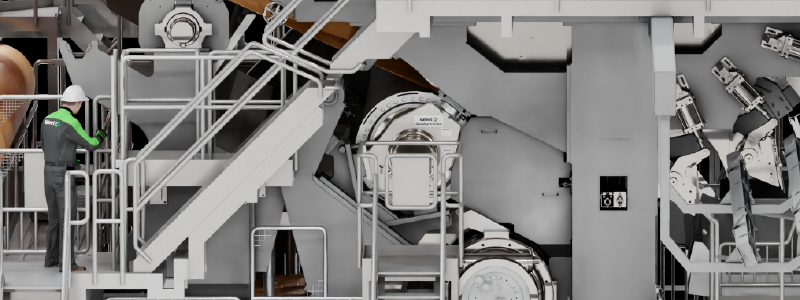

A successful cooperation between FPInnovations, Canfor and PulpEye has resulted in the world’s first technology for measurement of fibre wall thickness. As the first pulp producer in the world, Canfor has installed the fibre wall thickness module, FWT, in four PulpEye units in their pulp mills.

FPInnovations has patented a technology for determining fibre wall thickness and fibril angle of individual fibres. The rapid and robust technology is based on an innovative light system for colorimetric based quantification of the desired properties. PulpEye has the worldwide rights and is now commercialising the technology as an add-on technology for the industry-leading PulpEye online pulp and fibre analyser system.

Fibre wall thickness is an important parameter as it influences the strength properties of the pulp, but so far it has not been possible to measure it online. There can be a number of reasons to measure fibre wall thickness online. It is an efficient method for raw material control to make sure that the mix of e.g. saw mill chips, roundwood from thinnings, different species etc. is done so that a consistent pulp quality is maintained. The FWT module can control the efficiency of a fibre fractioning process. By measuring fibre wall thickness it is possible to calculate strength data and suggest level of refining to pulp customers, helping them achieve the requested paper and board strength properties.

The FWT module is based on optical measurement of a continuous fibre stream of a controlled concentration passing the patented* module. Cellulose is an anisotropic material and hence polarises light in two wave planes perpendicular to each other and with different refractive indices. In the FWT module, LED light of specific wavelengths is sent through the fibre stream and the resulting light is picked up by a colour camera. The result is an image where the fibres are visualised and wall thickness is shown in different colours.

“This Swedish-Canadian cooperation is a good example of bringing the best from each partner to develop a ground breaking technology,” says Öjvind Sundvall, MD PulpEye. “Ho Fan Jang at FPInnovations has developed and patented this technology. PulpEye has the equipment where the FWT module is perfectly integrated and Canfor Pulp took part in the development with their pulp knowledge and made the first mill installations.”