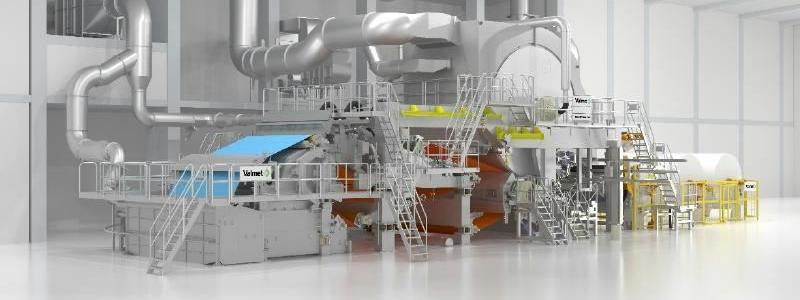

Valmet announces that it will supply Domtar with the equipment and technical services to convert a paper machine from uncoated freesheet to fluff pulp at Domtar's Ashdown, Arkansas (USA) pulp and paper mill.

The delivery is part of Domtar's USD 160 million project to re-purpose the mill's A64 paper machine.

The rebuilt machine is scheduled to begin operation in the third quarter of 2016.

The value of Valmet's delivery has not been disclosed.

"Valmet has been a trusted vendor-partner of ours, one that understands our business and delivers top-quality equipment and services that help our company succeed," says Jack Bray, Domtar's Vice President Manufacturing, Region 2.

The scope of the delivery includes a new wet end, upgrades to existing cylinder dryer section, a new fully automated reel and a new OptiWin Pulp winder. Also included is a bypass run to a new cutter-layboy with an automated bale handling line.

"Valmet has extensive experience in repurposing pulp and paper assets, especially in the production of fluff pulp," said Frank Swietlik, General Manager, Pulp Dryers and Baling, Valmet. "As we did during the Plymouth NC5 conversion, we worked closely with Domtar to optimize the technical solution that would meet their project objectives, including world class quality standards and high efficiency runnability."