Valmet’s innovative energy recovery system, Advantage ReTurne, has delivered positive results at Sofidel’s tissue mill in Italy.

The system was first installed at Sofidel’s tissue mill. "The first installation of the Advantage ReTurne energy saving system has been a positive experience for us. Its energy saving capabilities turned out to be better than we hoped for and well in line with our target to further reduce our CO2 emissions before the end of 2020," said, Simone Capuano, Vice Chief Technical Officer, Sofidel.

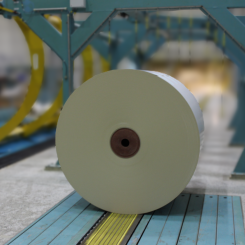

Valmet introduced Advantage ReTurne in a bid to enhance the energy efficiency of tissue production lines. The system is installed in the forming section. It recovers 50 percent of the energy from the headbox drainage water and via a generator converts it to electrical power which supplies the sectional drives. The Advantage ReTurne does not affect the formation of the paper or the tissue making process, it is easy to handle and has low maintenance need.

Jan Erikson, VP Sales, Valmet, said, "We had high expectations of the results from the first installation of the Advantage ReTurne system which was substantially exceeded. The installation went smoothly and the machine was running at full speed within five days. But the most exiting was that the energy recovery proved to be above guaranteed level."