Oilon manufactures oil, gas and dual fuel burners for domestic, industrial, power plant and different process applications.

– We offer comprising low NOx combustion systems including industrial burners for Paper and Chemical Industry. These burners can also be used for production of process steam and cooking of cellulose, told energy manager, Tapio Murtonen recently to Branschnyheter at company´s headquarter in Lahti, Finland.

Murtonen explained that Oilon International Oy is not just a leading global environmental and energy company, present in 35 Countries. Oilon is also more than 50 year old private family-owned company.

The company employs almost 300 people in production facilities in Finland and China. Projects resulted during year 2011 in annual sales of €58 million with 30% growth.

– Oilons long experience in combustion technology has resulted in reliable burners with low emission levels. Oilon’s reputation is based on successfully manufacturing various heating solutions for over 50 years. Today, we can offer our customers ever more reliable and modern burners for a multitude of tasks and operating environments, Tapio Murtonen told.

The company has delivered among other components even so called recovery boilers, lime kiln and odorous gas incineration technology to pulp and paper mill near city of Pietarsaari.

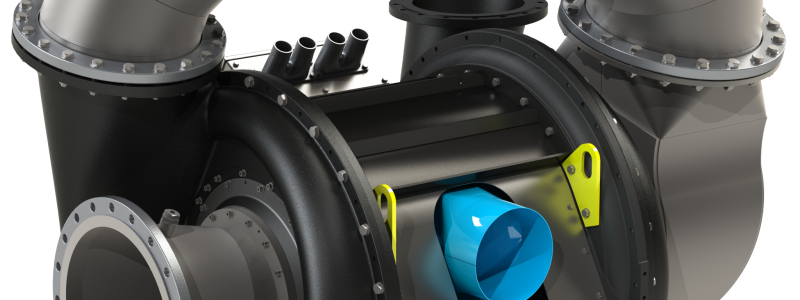

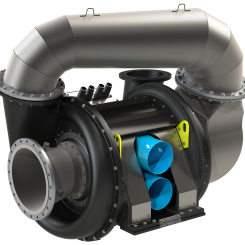

Murtonen referred especially to recently developed LENOX low NOx burners. Lenox is designed for power plant boilers fulfilling the stringent emission requirements.

– This achievement of technology is based on staged combustion. Fuel is lead into different zones of the flame, said Murtonen.

Combustion air is divided in Lenox into individually controlled chambers in wind box and directed also in stages to the flame. These fuel and air fl ows cause optimal air envelopes inside and around the flame resulting in long residence time and low emissions.

If the requirements of emission levels are according to Murtonen, very demanding, flue gas recirculation is an option to Lenox.

The metropolis of Beijing invested into cleaner energy production in order to reduce the city’s emissions. Among other things, lower emissions are aimed at by utilisation of Oilon’s Low-NOx burner technology.

– Over the years, Oilon has already delivered over 5,000 MW of environmentally friendly thermal power to Beijing. In all, burners worth a total of over 30,000 MW have been delivered to China, said Murtonen.

In Finland the Oilon group includes the administrative parent company, Oilon International Oy, and the subsidiaries Oilon Oy and Oilon Energy Oy, which produce oil and gas burners. The Finnish organisation also includes Geopro Systems Oy which develops and markets ground source heat pumps, and Ecopower Technology Oy which specialises in pressurised combustion systems.

The company’s foreign offices include sales offices Oilon GmbH in Germany, Oilon Polska Sp.z o.o. in Poland, OOO Oilon in St. Petersburg, Moscow and Ekaterinburg in Russia, and Oilon China Ltd. in Hongkong and Wuxi in mainland China.