Decor base paper maker from Quzhou, China, has contracted Voith to supply the key components for its new PM 3. After its previous excellent operating experience, Kingdecor has now called on Voith for the fourths time. Voith has already delivered key equipment for the PM 13, PM 1 and PM 2.

The components from Voith support the paper maker in achieving the highest quality and efficiency. Among other things, the delivery includes the Advanced Wet End Process concept. It will be planned based on the requirements of the paper machine. Standardized components will be used and adapted to the local conditions during the planning phase. For Kingdecor, it will be attuned to the needs of specialty papers with very high filler content.

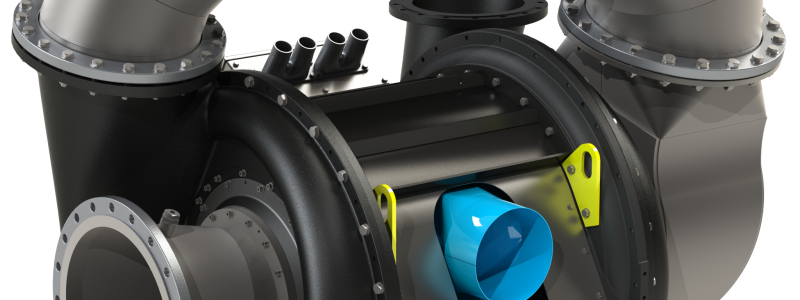

Also included in the delivery is the globally successful MasterJet headbox and the reaction force-free shaking unit DuoShake for improved Kingdecorfiber orientation thanks to high frequency shaking of the breast roll. The EcoSoft Delta soft nip calender for the best smoothness properties completes the delivery. It is distinguished by an easy roll change, very high reliability, and compact construction.

Kingdecor is a joint venture of the German Schattdecor AG and the Chinese Zhejiang Xianhe Special Paper Co., Ltd. With a wire width of 4,500 mm, the PM 3 will produce decor papers in the basis weight range from 30 g/m² to 150 g/m², with a maximum production speed of 750 m/min. The startup of the PM 3 in Quzhou is planned for the spring of 2014.